8 Year Exporter Solar Tracker Slewing Drive - slewing drive for solar tracker with 24V DC motor – Wanda

8 Year Exporter Solar Tracker Slewing Drive - slewing drive for solar tracker with 24V DC motor – Wanda Detail:

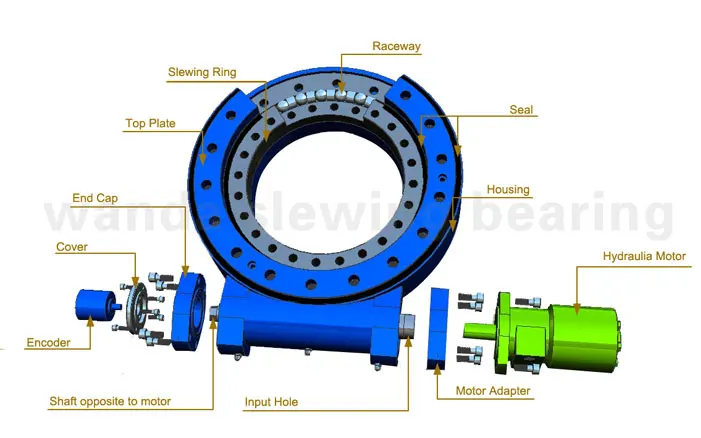

SLEWING DRIVE

By adopting slewing bearing as its core component,slewing drive can bear axial force, radial force and tilting moment

simultaneously. Slewing drive is widely applied in modular trailers, all types of cranes, aerial working platform, solar tracking

systems and wind power systems.

Electric and planetary gearboxes can be designed according to customer’s requirment.Slewing drive has the advantage for saving

space in facilities,max load capacity in a compact design,extensive lifespan, reduced maintenance costs.Glossary

Tilting Moment Torque: Torque is the load multiplied by distance between the position of load and the center of slewing bearing.

If the qorque generated by load and distance is greater than the rated tilting moment torque, slewing drive will be overturned.

Radial load: Load vertical to the axis of slewing bearing

Axial load: Load parallel to the axis of slewing bearing

Holding torque:It is the reverse torque.When the drive is rotating reversely, and parts are not damaged,The maximum torque

achieved is called holding torque.

Self-locking: Only when loaded, the slewing drive is not able to reverse rotate and thus called self-locking.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

To get the stage of realizing dreams of our employees! To build a happier, more united and much more skilled crew! To reach a mutual benefit of our prospects, suppliers, the society and ourselves for 8 Year Exporter Solar Tracker Slewing Drive - slewing drive for solar tracker with 24V DC motor – Wanda , The product will supply to all over the world, such as: Croatia, Malta, Lyon, We've been persisting in the business essence "Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying products and service. " Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.