Best-Selling Three Roller Slewing Ring - XZWD|Heavy Duty Three Row Roller Slewing Bearing for Tunnel boring machine – Wanda

Best-Selling Three Roller Slewing Ring - XZWD|Heavy Duty Three Row Roller Slewing Bearing for Tunnel boring machine – Wanda Detail:

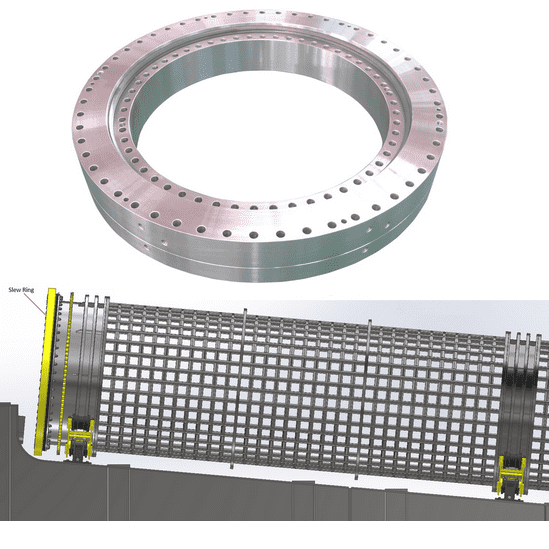

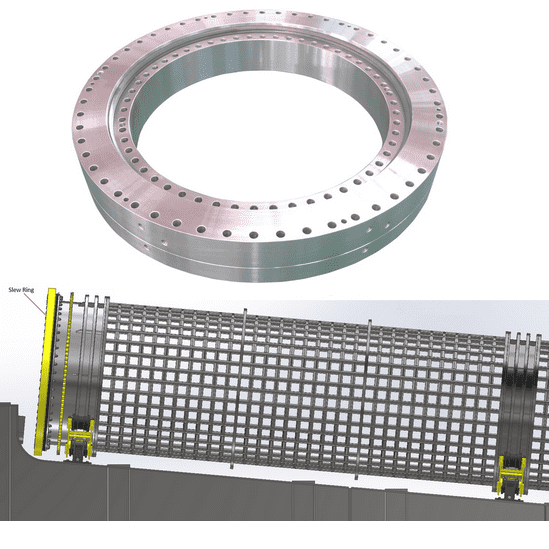

XZWD|Heavy Duty Three Row Roller Slewing Bearing for Tunnel boring machine

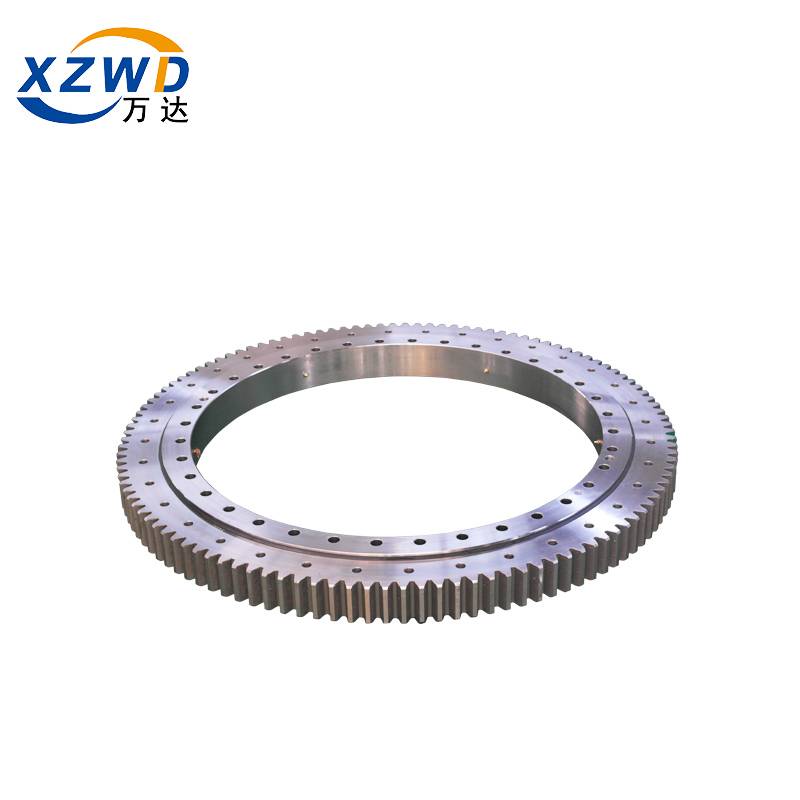

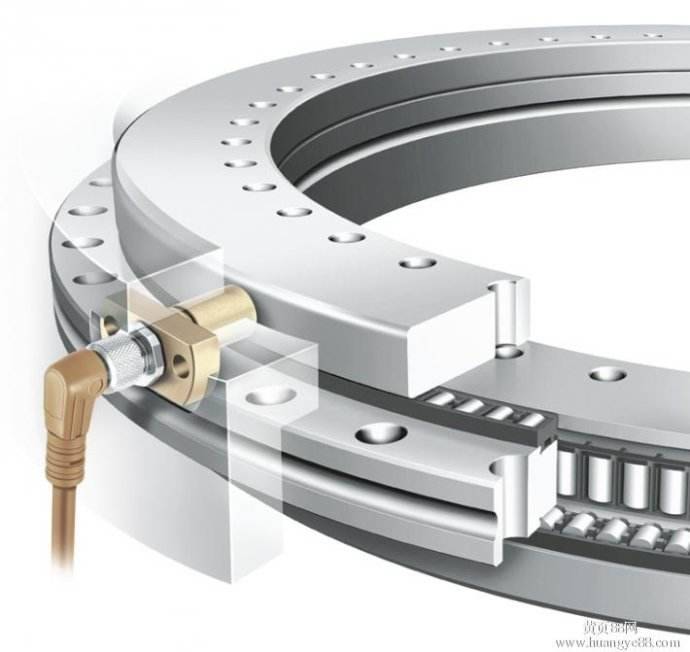

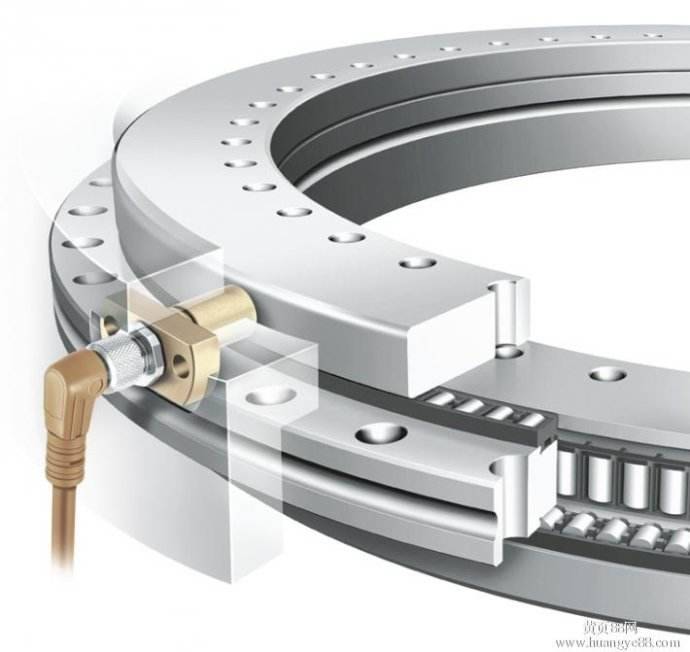

The three row roller slewing bearing is a kind of three row’s roller type pivoting support structures as claimed in claim 1 is characterized in that: the inner ring mounting hole that on inner ring, offers axial setting; On outer ring, offer the outer ring mounting hole of axial setting; Distance between the axis of the axis of inner ring mounting hole and main shaft is less than the distance between the axis of the axis of outer ring mounting hole and main shaft ; Offer a last trim ring mounting hole that cooperates with inner ring mounting hole at last trim ring, last trim ring offers trim ring mounting hole on another that cooperates with outer ring mounting hole.

The three row roller slewing bearing is a kind of three row’s roller type pivoting support structures as claimed in claim 1 is characterized in that: the inner ring mounting hole that on inner ring, offers axial setting; On outer ring, offer the outer ring mounting hole of axial setting; Distance between the axis of the axis of inner ring mounting hole and main shaft is less than the distance between the axis of the axis of outer ring mounting hole and main shaft ; Offer a last trim ring mounting hole that cooperates with inner ring mounting hole at last trim ring, last trim ring offers trim ring mounting hole on another that cooperates with outer ring mounting hole.

A tunnel boring machine (TBM), also known as a “mole”, is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata. They may also be used for microtunneling. They can be designed to bore through anything from hard rock to sand. It always use the three row roller slewing bearing.

The slewing bearing can rotate independently in three directions; the slewing bearing has simple, compact and reasonable structure; and the slewing bearing has high cost performance, is convenient to maintain, and satisfies the requirements of accuracy, bearing and multi-function of the device.

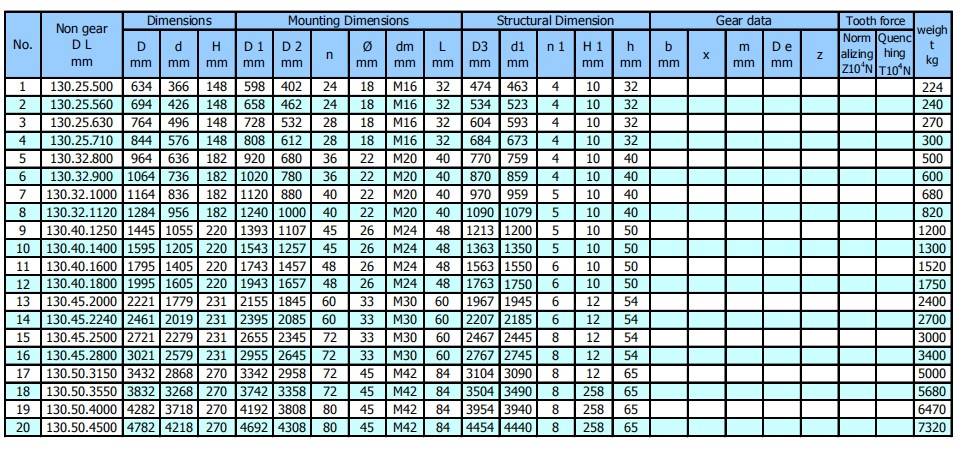

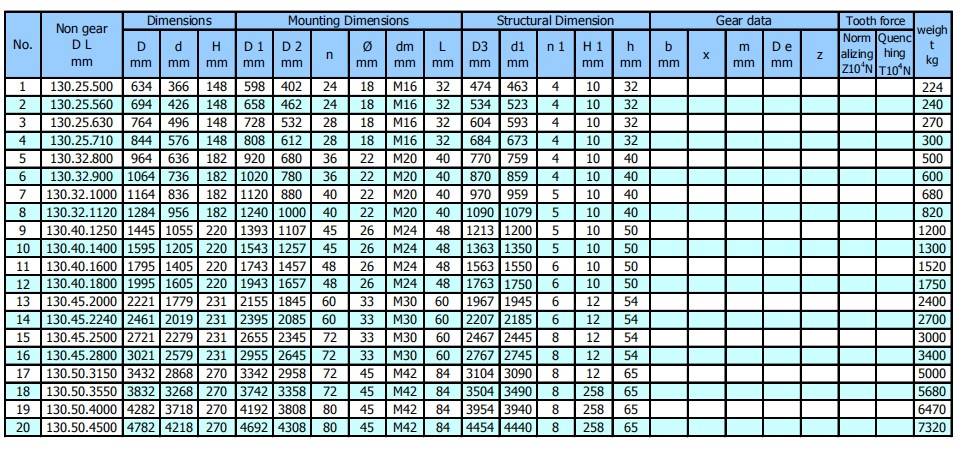

Please see attached slewing ring catalogue to find out which model you need.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for Best-Selling Three Roller Slewing Ring - XZWD|Heavy Duty Three Row Roller Slewing Bearing for Tunnel boring machine – Wanda , The product will supply to all over the world, such as: Durban, UAE, New Delhi, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.