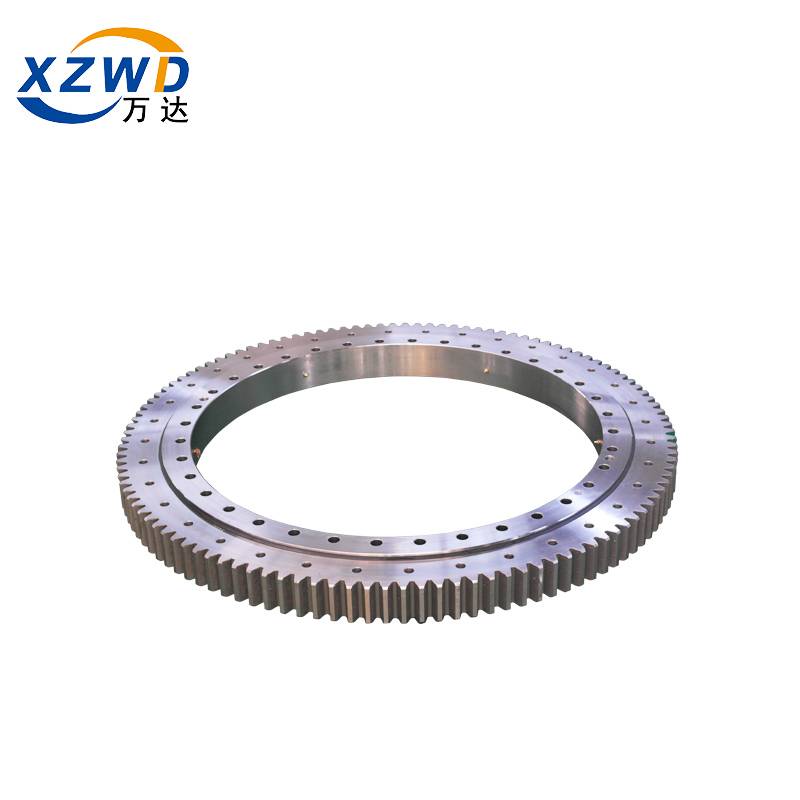

Big Discount Lazy Susan Bearing - 4 point angular contact ball turntable slewing ring – Wanda

Big Discount Lazy Susan Bearing - 4 point angular contact ball turntable slewing ring – Wanda Detail:

The slewing bearing industry is a capital-intensive and technology-intensive industry. After years of development, the Xuzhou slewing bearing industry has initially established relatively perfect industry standards. The research and

development capabilities of slewing bearing companies have been greatly improved, but compared with developed countries, they are developing and manufacturing technology development, process equipment and testing instruments. There are

still some gaps in such aspects.

In order to expand its share in the high-end market, Xuzhou’s relatively strong slewing bearing manufacturers with capital and technical strength are continuously increasing their investment in R&D. For example, Slewing Ring has been developing industry standards since 2011. More stringent corporate internal standards to ensure that the slewing bearing geometry is further improved; the depth of the hardened layer is increased; the service life of the slewing ring is increased; the research and development of anticorrosive materials is strengthened; and the application of the slewing ring is promoted; The development of equipment, the use of computer simulation technology for

the effective validation of slewing ring bearing capacity, the product structure into the size of the optimization design. At the same time, many enterprises in Xuzhou slewing bearing also began to pay attention to the research and application of the slewing ring basic technology and related technologies.

It should be said that in recent years, xuzhou slewing bearing has developed rapidly and the quality of slewing bearings is high. At the same time, combined with the continuous improvement of the company’s operating capacity and production efficiency, Xuzhou slewing bearings have always maintained a competitive advantage in the domestic market in the domestic market.

Many users did not know enough about the installation of the slewing ring, often resulting in improper operation of the slewing ring due to installation errors or inaccuracies, such as inflexible rotation, abnormal sound, etc., today led by Learn how to install slewing rings and slewing bearings so that everyone can reduce problems and mistakes in installing slewing rings.

First, before installing the slewing ring, it is necessary to inspect the mounting surface of the main machine. It is required that the supporting member should have sufficient strength, the connecting surface should be machined, and the surface should be smooth and free of debris and burrs. For those that cannot be machined to achieve the required flatness, special plastics with high injection strength can be used as fillers to ensure the accuracy of the mounting plane and to reduce vibration. The slewing ring of the slewing bearing has a hardened soft zone, which is marked with S on the end face of the ferrule. When installing, the flexible tape should be placed in the non-load zone or in the non-

recurrent zone (the plug hole is always located in the soft zone. ).

Second, when installing a slewing ring, radial positioning should be performed first, cross-tighten the mounting bolts, and check the rotation of the bearing. In order to ensure smooth bearing transmission, the gears should be inspected before the mounting bolts are tightened. When tightening the bolt, there should be enough pre-tightening force, and the pre-tightening force should be 70% of the yield limit of the bolt material. The mounting bolts should be equipped with flat washers. It is forbidden to use spring washers. After the installation of the slewing bearing is completed, it is put into operation. After 100 hours of continuous operation, it is required to fully check whether the pre- tightening torque of the mounting bolt meets the requirements. The above inspection is repeated once every 500 hours of continuous operation.

Third, the slewing ring should be filled with an appropriate amount of grease after installation, and should be filled with side slewing bearings so that the grease is evenly distributed. After a period of working time, the slewing ring bearing will inevitably lose a part of the grease. Therefore, the slewing ring bearing should be replenished once every 50 to 100 hours in normal operation. For slewing bearings that operate in high temperature environments or in dusty conditions, the period for adding lubricating grease should be appropriately shorter. When the machine is to be shut down for storage, it must also be filled with sufficient grease.

4. During the transportation process, bearings should be placed horizontally on the vehicles. Measures should be taken to prevent slipping and prevent vibration. If necessary, add auxiliary supports.

5. Bearings should be placed horizontally on a dry, ventilated, and flat site. Storage should be isolated from chemicals and other corrosive materials. If multiple sets of bearings need to be stacked and stacked, three or more equal-height wooden spacers should be placed uniformly in the circumferential direction between each set, and the upper and lower spacers should be placed in the same position. Bearings that need to continue to be stored beyond the rust-proof period should be cleaned and rust-proofed again.

Product detail pictures:

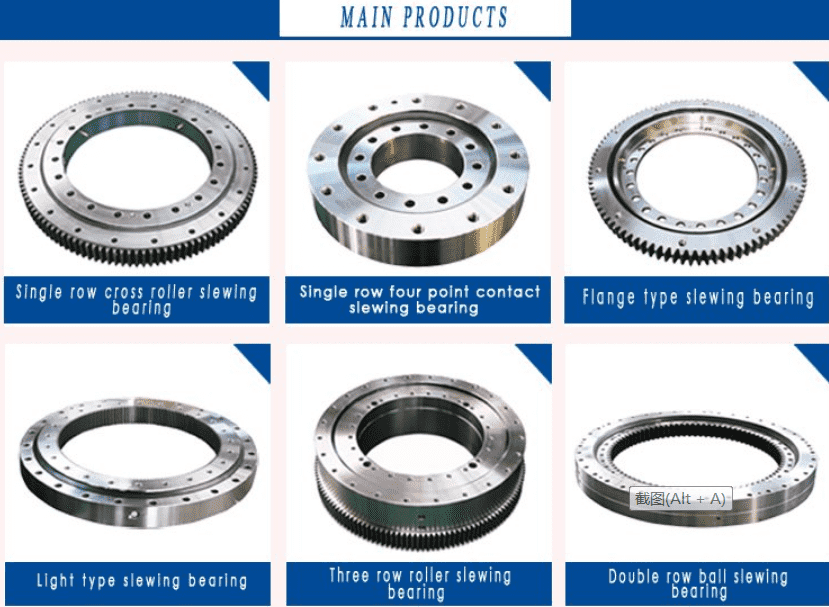

Related Product Guide:

Car parking system used slewing bearing

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for Big Discount Lazy Susan Bearing - 4 point angular contact ball turntable slewing ring – Wanda , The product will supply to all over the world, such as: Curacao, Uruguay, Costa Rica, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.