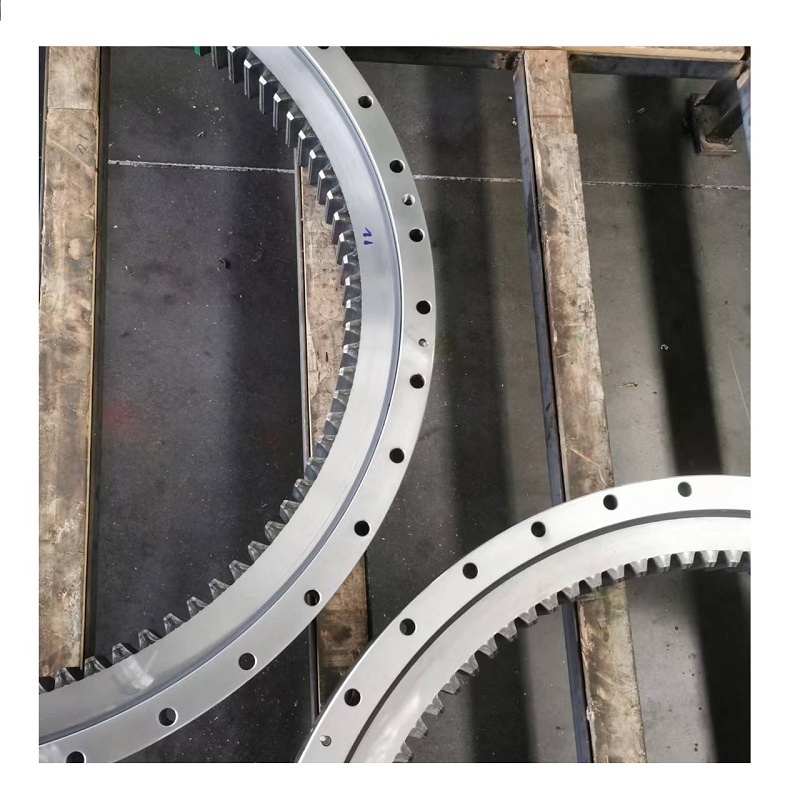

Customized light weight excavator slewing ring bearing

Light excavator slewing bearing

The slewing bearing of a light excavator is easily damaged. Usually the replacement cycle is 2 to 3 years. In this case, the main bearing failure is the broken teeth of the slewing ring, abnormal noise when rotating or the slewing ring is stuck. When this happens, stop the operation immediately, otherwise the rotating motor may be damaged.

Objectively, it is unfair to put all the blame on the bearing quality, because the slewing ring of the light excavator has a large rotation radius. Overwork is sometimes required, causing the teeth to wear and eventually break. In addition, the operation method of the excavator driver will also affect the service life of the slewing bearing.

Slewing rings have high stiffness and load-carrying capacity, and we can provide customized types, such as tooth hardening, which can improve the wear resistance and service life of slewing rings. Special finishes or extreme environments are also available.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.