double row ball slewing bearing with different ball diameter 021.40.1400

Slewing bearing is also called turntable bearing, some people also call it: rotary bearing, slewing bearing.

English Name: sliding bearing or sliding ring bearing or turning bearing

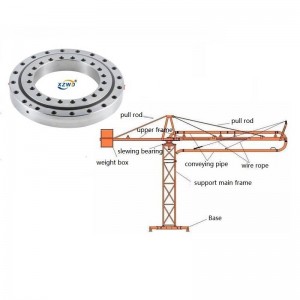

Slewing bearing is a kind of large bearing which can bear comprehensive load. It can bear large axial, radial load and overturning moment at the same time. Generally, slewing bearing is equipped with mounting hole, internal or external gear, lubricating oil hole and sealing device, which makes the design of main engine compact, easy to guide and easy to maintain. There are four series of slewing bearing: toothless, external and internal four point contact ball bearing, double row angular contact ball bearing, cross cylindrical roller bearing, cross tapered roller bearing and three row cylindrical roller composite bearing. Among them, four point contact ball bearing has higher static load capacity, cross cylindrical roller has higher dynamic load capacity, and cross tapered roller bearing has higher pre load capacity Interference can make the bearing have greater support rigidity and rotation accuracy. Due to the increase of bearing capacity, the three row cylindrical roller combined bearing leads to the bearing height, and various forces are borne by different raceways respectively. Therefore, the bearing diameter can be greatly reduced under the same stress, so the main engine is more compact. It is a slewing bearing with high bearing capacity. Slewing bearing is widely used in large-scale slewing device of hoisting machinery, mining machinery, construction machinery, port machinery, ship machinery, high-precision radar machinery and missile launcher. At the same time, we can also design, develop and produce all kinds of special structure slewing bearing according to the specific requirements of users.

application

Slewing bearing is widely used in real industry, which is called “the joint of machine”. It is mainly used in truck crane, railway crane, port crane, marine crane, metallurgical crane, container crane, excavator, filling machine, CT standing wave therapeutic instrument, navigator, radar antenna pedestal, missile launcher and tank And robots and rotating restaurants.

construction machinery

Slewing bearing is widely used. Construction machinery is the first and most widely used place of slewing bearing, such as earthwork machinery, excavator, disintegrator, stacker reclaimer, grader, road roller, dynamic rammer, rock drilling machine, roadheader, etc. Others are:

Concrete machinery: concrete pump truck, concrete mixing boom integrated machine, belt spreader

Feeding machinery: disc feeder, sand mixer

Lifting machinery: wheel crane, crawler crane, portal crane, tower crane, fork crane, crane, gantry crane Foundation treatment machinery: percussive reverse circulation drilling rig, rotary drilling rig, percussive rotary drilling rig, rotary drilling rig, reverse circulation rotary drilling rig, positive circulation rotary drilling rig, long spiral engineering drilling rig, diving drilling rig, static pressure pile driver and pile driver

Engineering ship: dredger

Special vehicles: bridge detection vehicle, fire truck, window cleaning machine, flat beam transport vehicle, aerial work vehicle, self-propelled aerial work platform

Light Industry Machinery: beverage machinery, bottle blowing machine, packaging machinery, filling machine, rotary bottle management machine, injection molding machine

Marine crane

Various equipment platforms

In addition to a variety of construction machinery, the application scope of slewing bearing has been gradually expanded. At present, similar equipment platforms such as port equipment, metallurgical equipment, drilling platform have begun to use slewing ring to replace the original bearing.

Port equipment: port crane and frontal crane

New energy equipment: wind power generation equipment, solar power generation equipment

Metallurgical equipment: metallurgical crane, ladle turret, steel grabbing machine, mud gun, oxygen blowing device

Amusement equipment: Ferris wheel, etc

Airport equipment: Airport tanker

Military equipment: radar, tank, etc

Robot: palletizing robot, welding robot, manipulator

Medical equipment: Gamma Knife

Environmental protection equipment: mud scraper

Parking equipment: tower garage

Drilling platform equipment, kitchen equipment, CNC equipment (wire cutting machine, quenching machine), brick machine

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.