factory customized 12 Lazy Susan Bearing - XZWD Single Row Crossed Roller Slewing Bearing Ring Tunnel Boring Machines – Wanda

factory customized 12 Lazy Susan Bearing - XZWD Single Row Crossed Roller Slewing Bearing Ring Tunnel Boring Machines – Wanda Detail:

With the increasing population, the worldwide demand for energy is growing rapidly. At the same time, however, the demand for renewable and environmentally friendly technologies is also growing. A promising approach is to produce energy

close to where it will actually be used. This means not only that transport losses can be reduced, but also infrastructure costs can be saved.

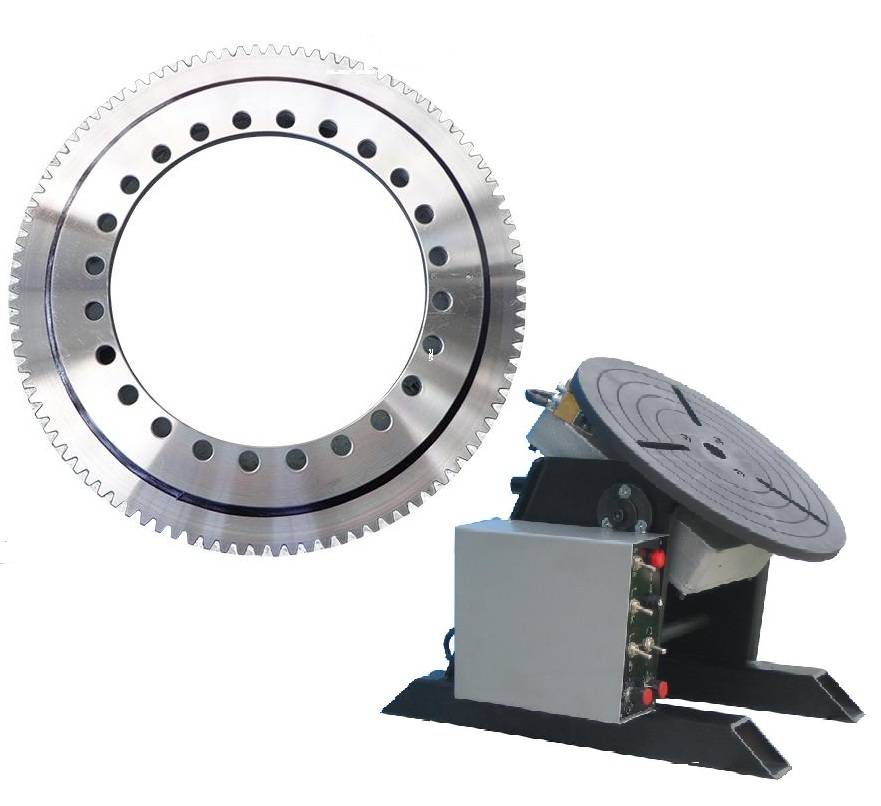

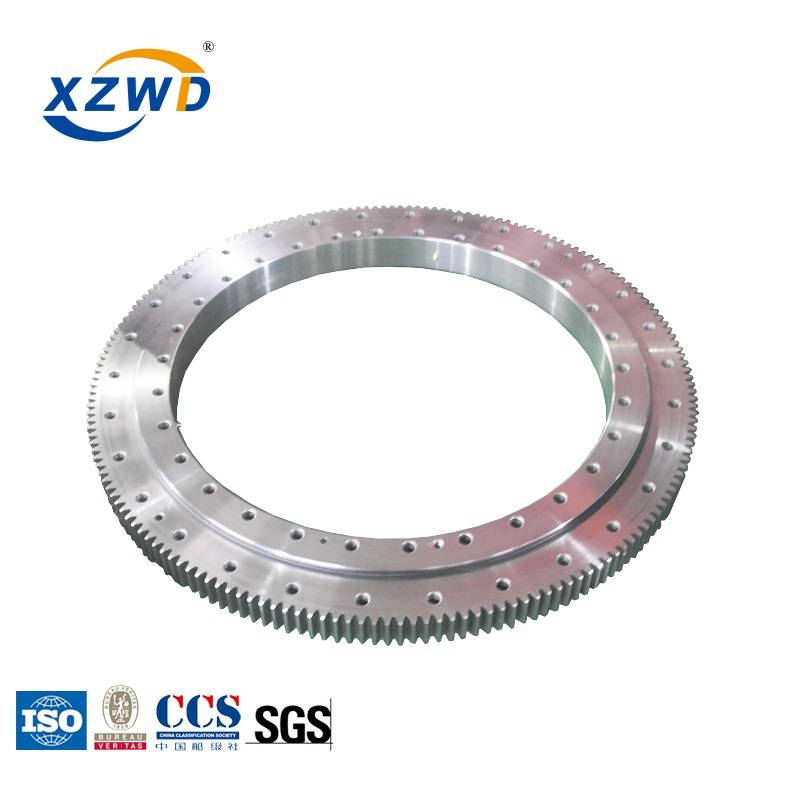

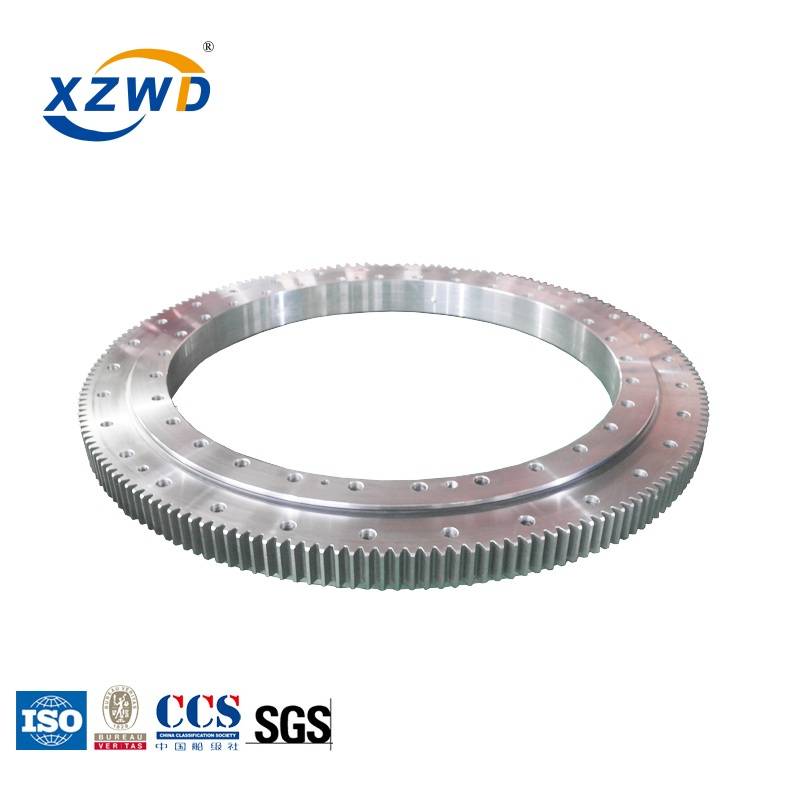

Slewing ring can bear axial, radial load and tilting moment load simultaneously. It can be combined with pinion, planetary gearbox and motors…

We have strict production schedule to assure the delivery time, the production schedule as below:

A. Forging purchase period: 15-20 days

B. Production process:

1. Rough turning: 2-3 days

2. Raceway heat treatment: 2 days

3. Fine turning: 2 days

4. Gear cutting: 4-5 days

5. Drilling: 2-3 days

6. Final turning: 2 days

7. Assembling and Inspection: 2 days

C. Packing and delivery to Port: 3-5 days

Totally about 40-50days

gas engines contribute to environmentally friendly and location-dependent energy production in combined heat and power units or gensets. Engine operation is possible with a wide variety of gases. As a result, waste products, for example

gas engines contribute to environmentally friendly and location-dependent energy production in combined heat and power units or gensets. Engine operation is possible with a wide variety of gases. As a result, waste products, for example

from biogas plants or sewage treatment plants, can be reused wisely.

In the area of earthmoving,we offers an extensive program of hydraulic excavators and duty cycle crawler cranes, crawler tractors and crawler loaders, telescopic handlers, wheel loaders and articulated trucks. Highest quality standards

are achieved by in-house production of main components which are developed and manufacture. Among these are the entire drive and control technology, diesel engines and a variety of components for hydraulics, gearboxes, and electronic

systems.

In order to accommodate the largest dimensions, the Liebherr portfolio also includes segmented large diameter bearings alongside its one-piece slewing bearings. Starting from a diameter of around 9.5 meters, the bearings can be produced

in this segmented format.

The large bearings, tailored individually to match the customer project, can be used for rotating thousands of tonnes of steel, and are characterised by their low torque and high load carrying capacity. In this way, We is able to

support the ongoing development of offshore machine construction, and the ever-larger dimensions at play in this sector.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for factory customized 12 Lazy Susan Bearing - XZWD Single Row Crossed Roller Slewing Bearing Ring Tunnel Boring Machines – Wanda , The product will supply to all over the world, such as: Bangladesh, Peru, Oslo, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.