factory low price Lazy Susan Bearing Mechanism - Professional slewing bearing manufacturer for welding positioner – Wanda

factory low price Lazy Susan Bearing Mechanism - Professional slewing bearing manufacturer for welding positioner – Wanda Detail:

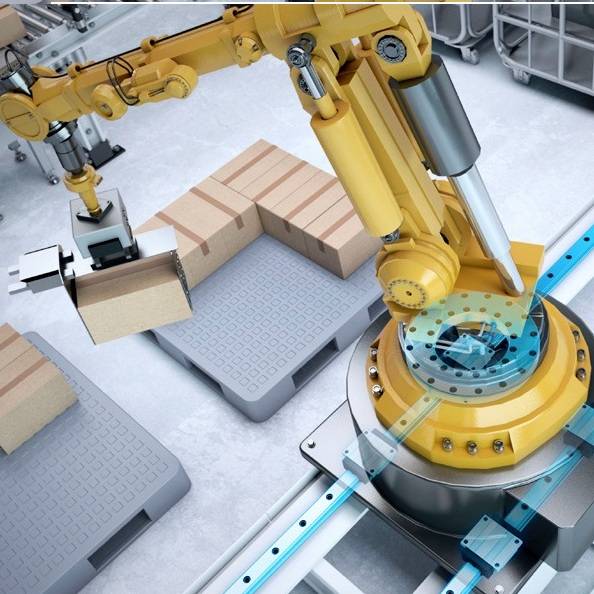

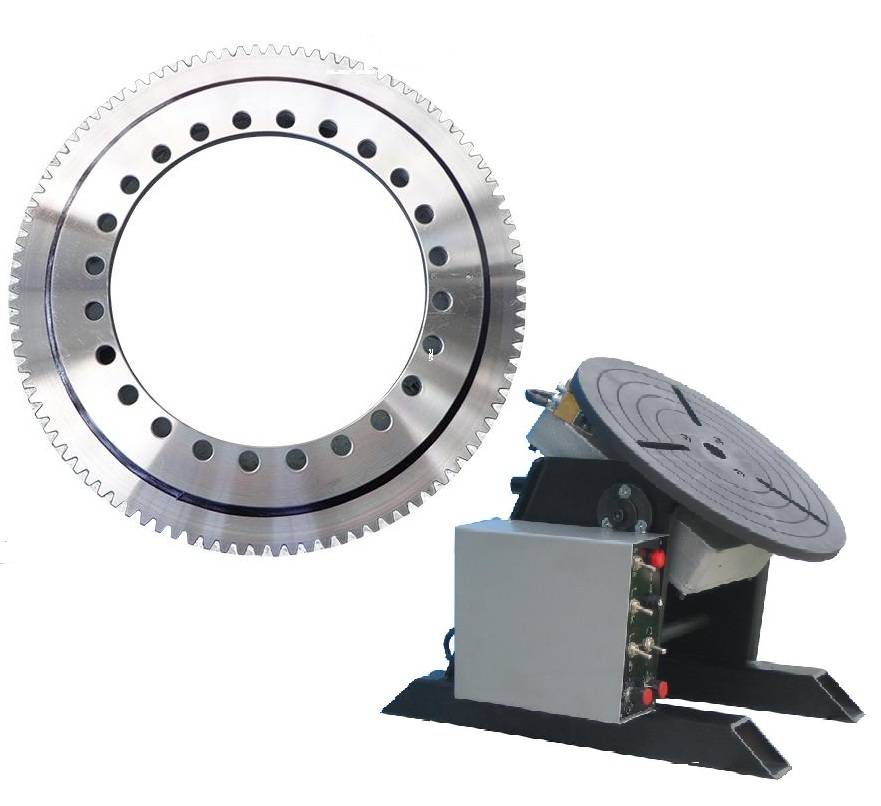

Welding positioners are designed to position the part in the optimal welding position.It is a kind of welding auxiliary equipment, it was known as the three planes in welding auxiliary equipment with welding manipulator,welding roller bed.The welding positioner mainly realizes rotation through slewing bearings.

The slewing mechanism transmission is shown in following Figure . Its transmission route is roughly: drive motor-slewing reducer-slewing bearing-workbench.

The worktable is fixed on the slewing bearing, and the slewing bearing is fixed on the support frame. The large gear on the periphery of the slewing bearing meshes with the pinion of the reducer output shaft, and the rotary motion of the table is formed by the drive of the motor which connected to the reducer input shaft.

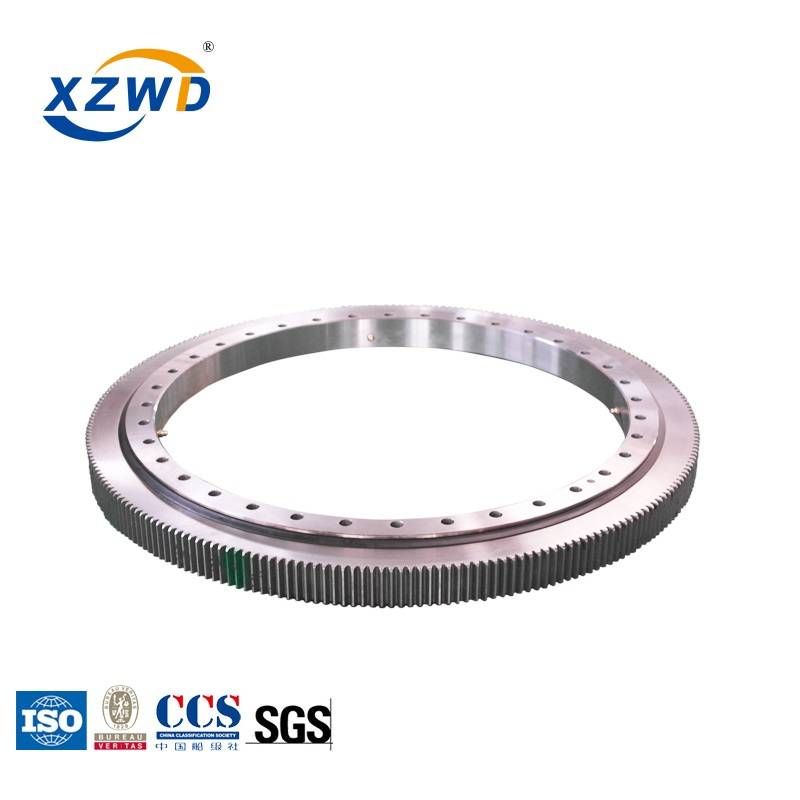

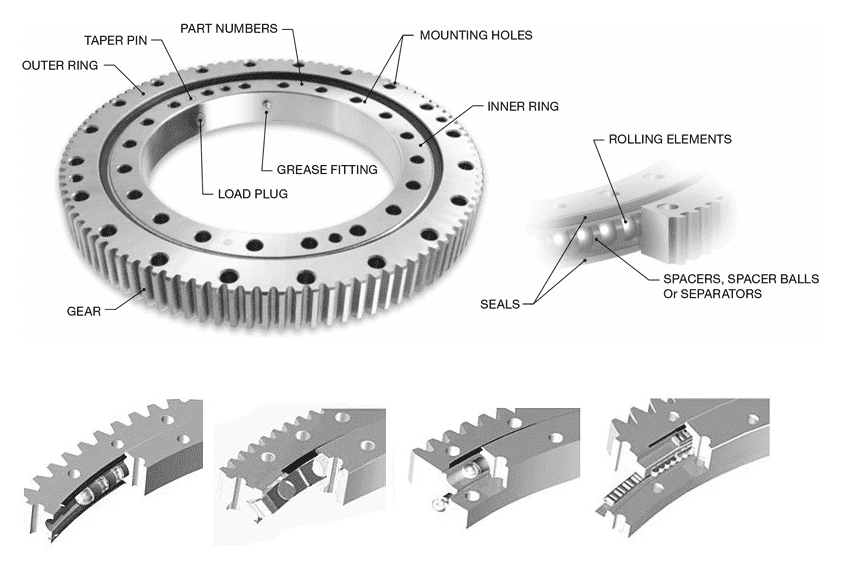

In the slewing system, the worktable is fixed on the slewing bearing, and the worktable is connected to the support frame through the slewing bearing. This not only improves the rotation accuracy of the worktable, but also improves the rigidity of the worktable. The single row four point contact ball slewing bearing is composed of two races. It has a compact structure and light weight. The steel ball makes four-point contact with the arc track. XZWD slewing bearing according to the request of welding positioner, the recommended slewing bearing type is 012. 60. 2000.

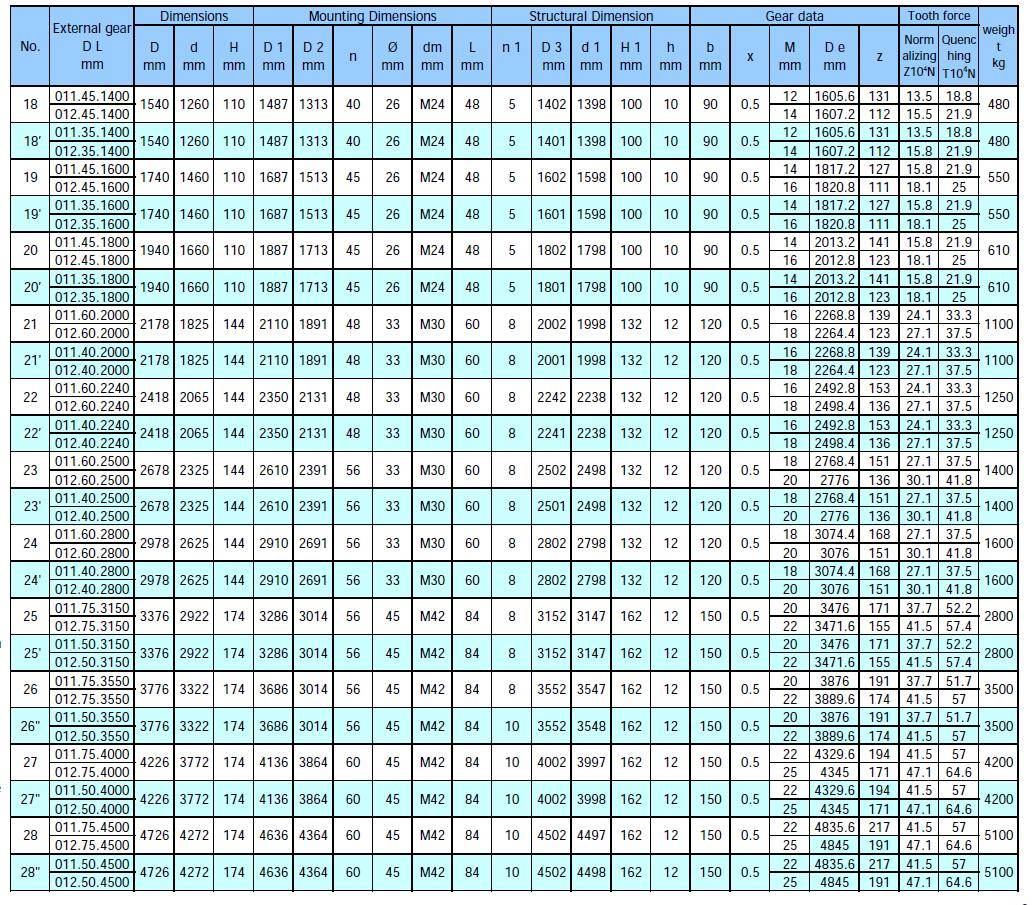

The following is our catalogue for slewing bearing, if you need any model, you can send email to me.

Also if you need the slewing bearing for welding positioners, please tell me your request by email, we could recommend and design the most suitable slewing bearing for you.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for factory low price Lazy Susan Bearing Mechanism - Professional slewing bearing manufacturer for welding positioner – Wanda , The product will supply to all over the world, such as: Philippines, Sweden, Iceland, Due to good quality and reasonable prices, our products have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly