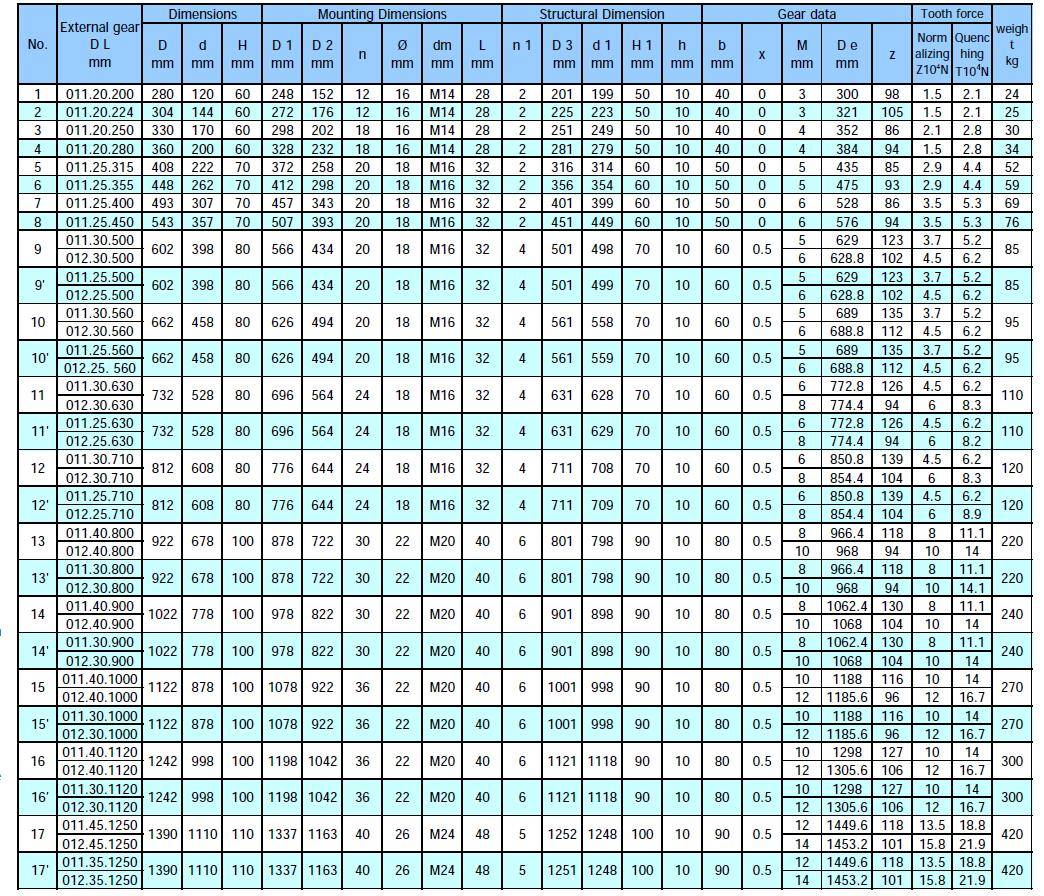

factory Outlets for Turnable Slewing Ring - xzwd OEM best price turntable ball bearing for crane – Wanda

factory Outlets for Turnable Slewing Ring - xzwd OEM best price turntable ball bearing for crane – Wanda Detail:

After installing the rollers and clearance cage, the separable inner ring (or outer ring) will be fixed with the shaft washer. In order to prevent the separation, the installation of the shaft washer should be simple. The clearance cage enables the friction between rollers to be disappeared and prevent rollers from falling down on one side, which is able to obtain a stable torque. The rollers are orthogonal arranged, so only one set of the Crossed Roller Bearings can withstand the loads from different directions. Compared with the traditional series bearing, the current series bearings have increased the level of rigidity by three to four times.

The crossed roller bearing is compact that reduces the thickness of the inner and outer ring to the lowest level. the bearing is suitable for position where the light weight, the compact style and he high-precision rotation in the inner ring are needed, such as the rotating part in mechanical watch.

Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2008 and GB/T19001-2008. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

without the mounting holes on both inner ring and outer ring, its requires a presser flange and housing for the installation. In addition, because it has an integrated inner/outer ring structure and is equipped with washers, the installation has little impact on its performance, which can achieve the stable rotation accuracy and torque. This series bearing can be used in the rotation areas of both outer ring and inner ring while dimensions of the bearing are smaller.

It has smaller sectional dimensions. Its outer ring is separable while the inner ring is integrated with the main body through three fixed rings. Since the inner ring and outer ring do not have the mounting holes, its requires a presser .

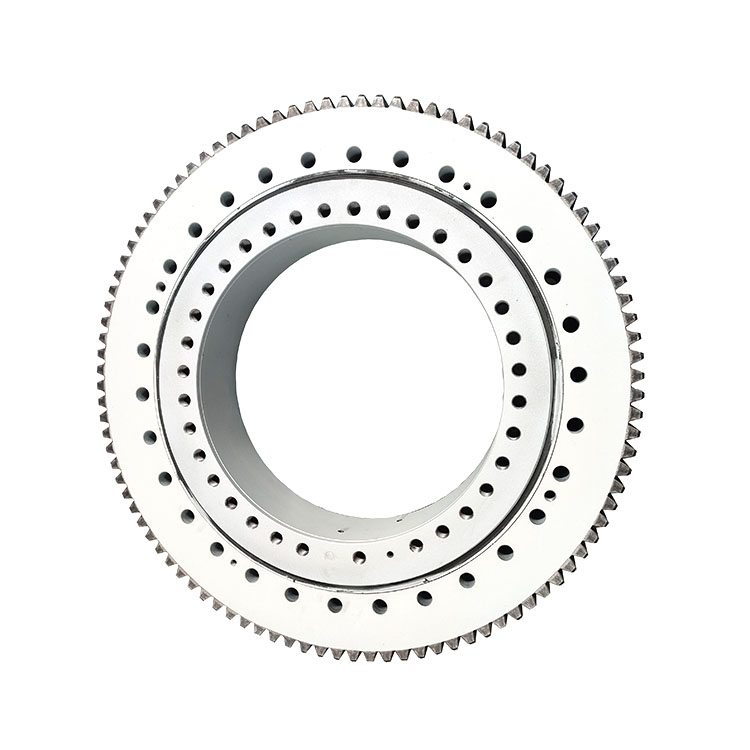

Turntable and Slewing Ring bearings utilize one to three rows of balls or rollers in order to provide smooth rotation even under extremely large loads. In addition to radial and axial loads, these bearings are able to support large moments in situations when loads are cantilevered away from the bearing’s central axis.

flange and housing for installation. This series bearing can be used in the areas where the inner ring requires high-precision rotation.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

As for aggressive rates, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such good quality at such charges we are the lowest around for factory Outlets for Turnable Slewing Ring - xzwd OEM best price turntable ball bearing for crane – Wanda , The product will supply to all over the world, such as: Malawi, Greece, Mexico, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!