Factory source Double Row Ball Slewing Bearing - Best price 4 point angular contact ball turntable slewing bearing | XZWD – Wanda

Factory source Double Row Ball Slewing Bearing - Best price 4 point angular contact ball turntable slewing bearing | XZWD – Wanda Detail:

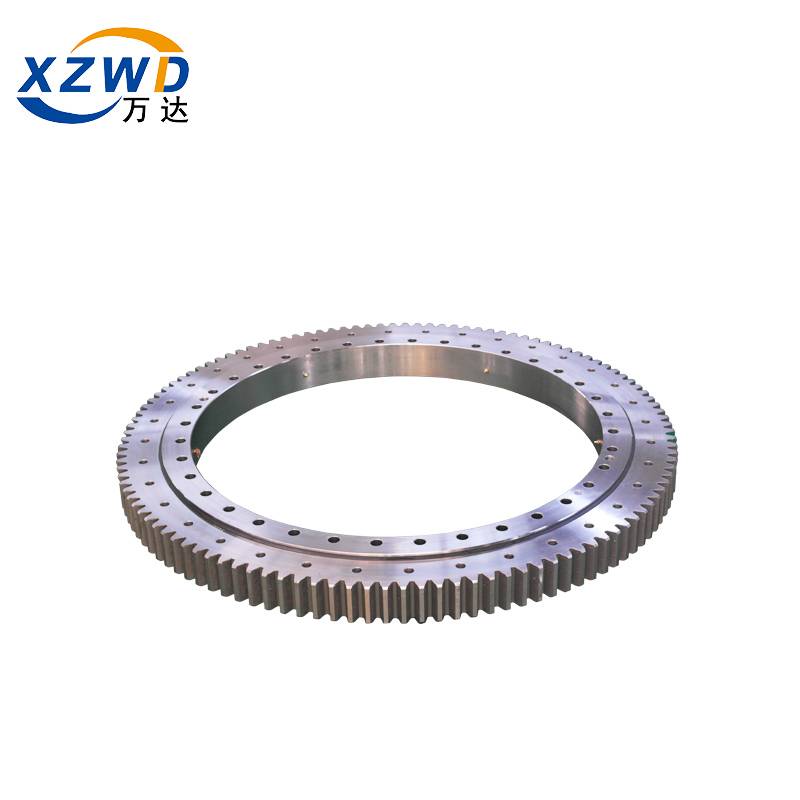

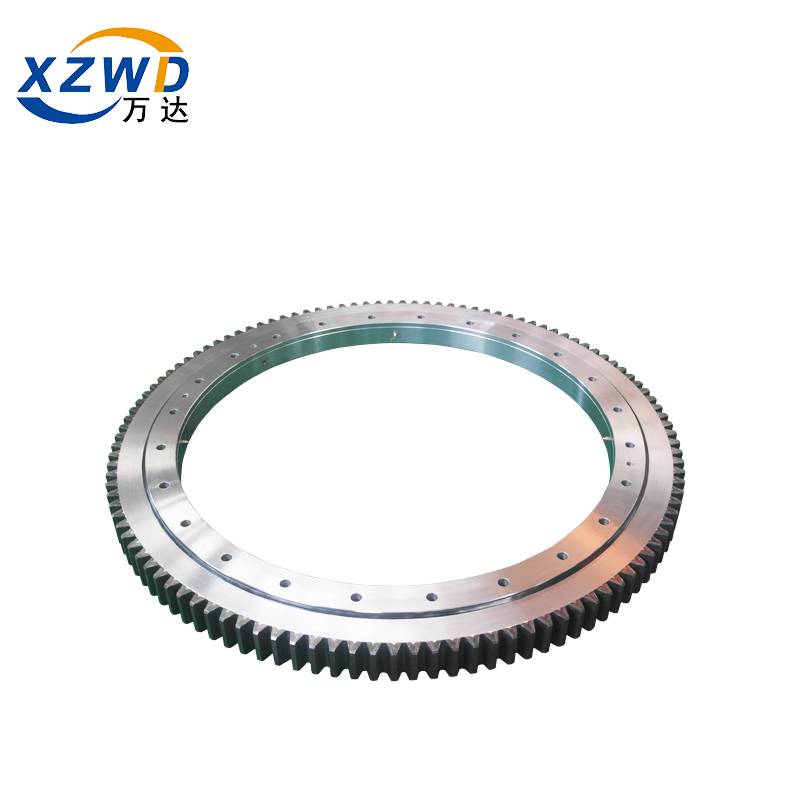

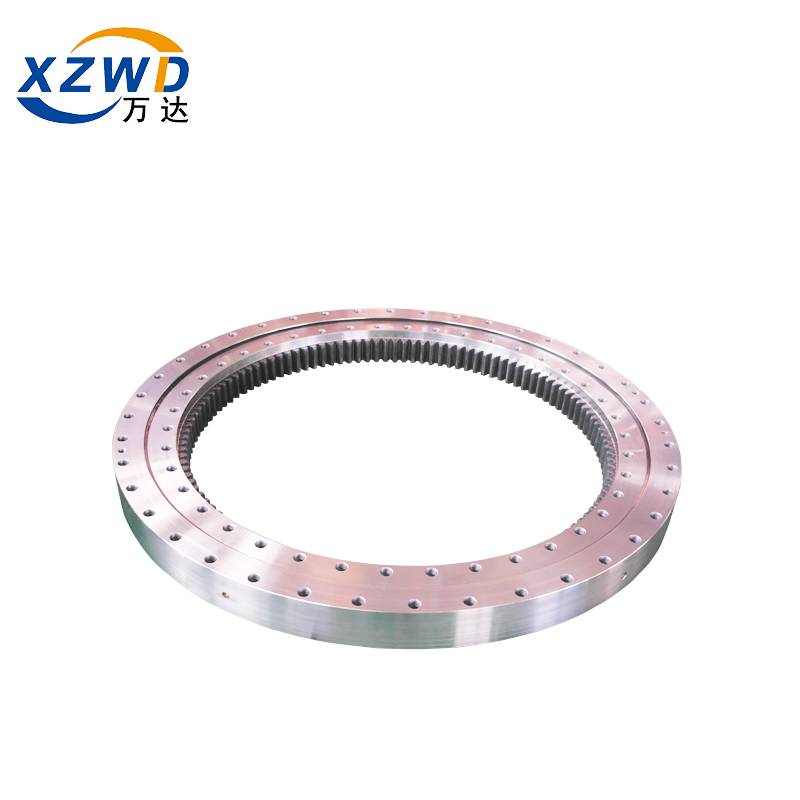

Some of the host construction machinery in harsh conditions, in order to improve the slewing bearing gear strength, gear hardness, gear wear resistance and gear toughness, we usually take the slewing ring gear teeth surface quenching process, otherwise the slewing ring gear will wear resistance, broken teeth and other failure problems. But after tooth quenching treatment, there will be deformation, gear tooth deviation usually hit the design requirements, in order to ensure that the standard, we usually use slewing ring.

On the basis of the basic crossed roller slewing bearings, many structural differences in the crossed roller slewing bearings are derived, so that they can be used for different requirements of the occasion. From the general category, it can be divided into: basic crossed roller slewing bearings, high rigidity crossed roller slewing bearings, ultra-thin crossed roller slewing bearings;

without the mounting holes on both inner ring and outer ring, its requires a presser flange and housing for the installation. In addition, because it has an integrated inner/outer ring structure and is equipped with washers, the installation has little impact on its performance, which can achieve the stable rotation accuracy and torque. This series bearing can be used in the rotation areas of both outer ring and inner ring while dimensions of the bearing are smaller.

It has smaller sectional dimensions. Its outer ring is separable while the inner ring is integrated with the main body through three fixed rings. Since the inner ring and outer ring do not have the mounting holes, its requires a presser .

without the mounting holes on both inner ring and outer ring, its requires a presser flange and housing for the installation. In addition, because it has an integrated inner/outer ring structure and is equipped with washers, the installation has little impact on its performance, which can achieve the stable rotation accuracy and torque. This series bearing can be used in the rotation areas of both outer ring and inner ring while dimensions of the bearing are smaller.

It has smaller sectional dimensions. Its outer ring is separable while the inner ring is integrated with the main body through three fixed rings. Since the inner ring and outer ring do not have the mounting holes, its requires a presser .

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Factory source Double Row Ball Slewing Bearing - Best price 4 point angular contact ball turntable slewing bearing | XZWD – Wanda , The product will supply to all over the world, such as: Denmark, Thailand, Rio de Janeiro, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.