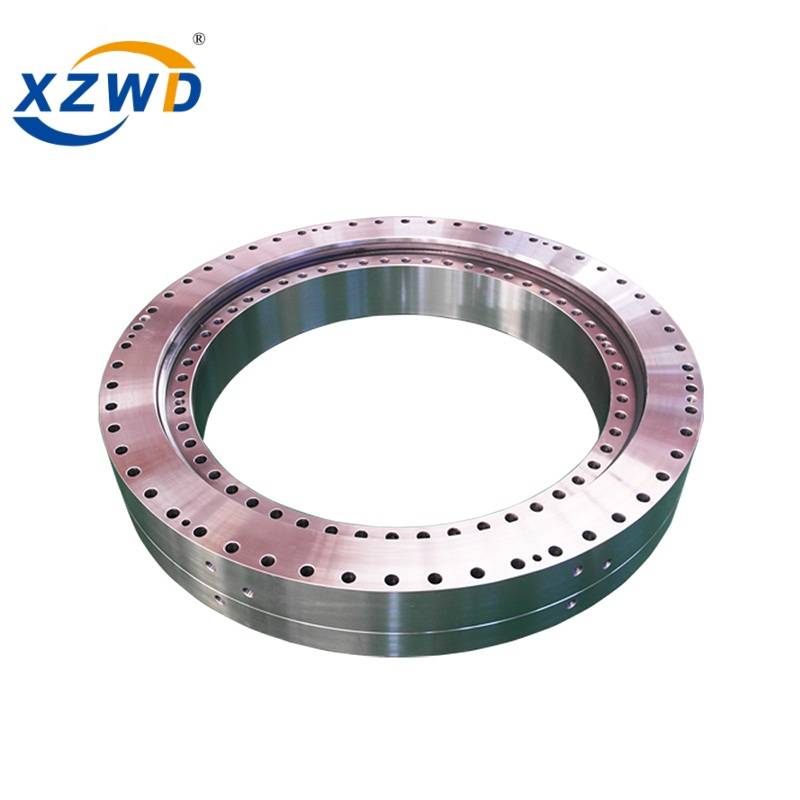

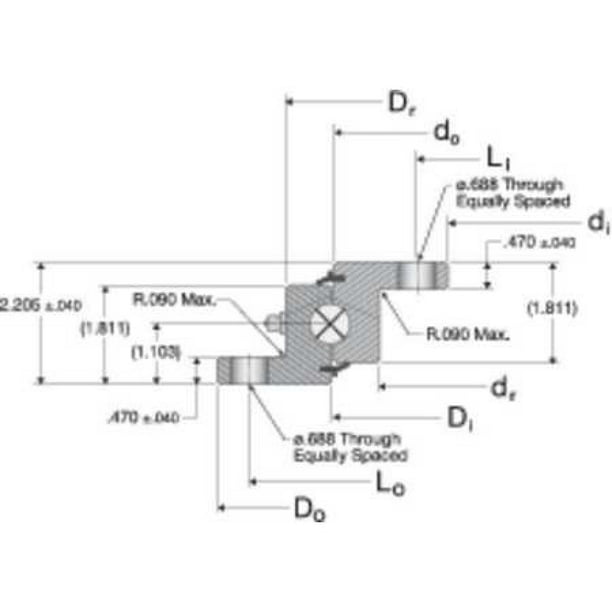

Factory supplied Slewing Ring Turntable - DOUBLE FLANGE SLEWING BEARINGS WITH SINGLE BALL BEARING ROW, NO GEAR TEETH, STANDARD 230 SERIES – Wanda

Factory supplied Slewing Ring Turntable - DOUBLE FLANGE SLEWING BEARINGS WITH SINGLE BALL BEARING ROW, NO GEAR TEETH, STANDARD 230 SERIES – Wanda Detail:

The flange slewing ring has the same structure with four points contact ball slewing bearing, but the weight is lighter; the outer or inner ring of the flanged slewing bearing has the “L” edge, like a flange, that’s why we called it flange type bearing. Flange light slewing bearing ring is also used for some applications which has weight limit for the bearing, the weight for the flange type slewing ring is much lower than normal type. The materials of the flange slewing ring are mainly 50Mn, 42CrMo and C45.

We have professional engineers and we have over 15 years experience in slewing bearings. Our factory was introduced lean manufacturing to promote our quality of the flange slewing bearing ring. The MOQ of our flange light slewing bearing is 1 piece.

The flange slewing bearing rings has been widely used in many applications:

1. Food machinery

2. Canning machinery

3.Environmental machinery

4.Car parking systems, etc

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our firm sticks to the basic principle of "Quality is the life of your company, and status will be the soul of it" for Factory supplied Slewing Ring Turntable - DOUBLE FLANGE SLEWING BEARINGS WITH SINGLE BALL BEARING ROW, NO GEAR TEETH, STANDARD 230 SERIES – Wanda , The product will supply to all over the world, such as: Mombasa, Belize, Birmingham, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!