Free sample for Slewing Drive With Motor - XZWD Precision Solar tracking Slewing drive SE5 – Wanda

Free sample for Slewing Drive With Motor - XZWD Precision Solar tracking Slewing drive SE5 – Wanda Detail:

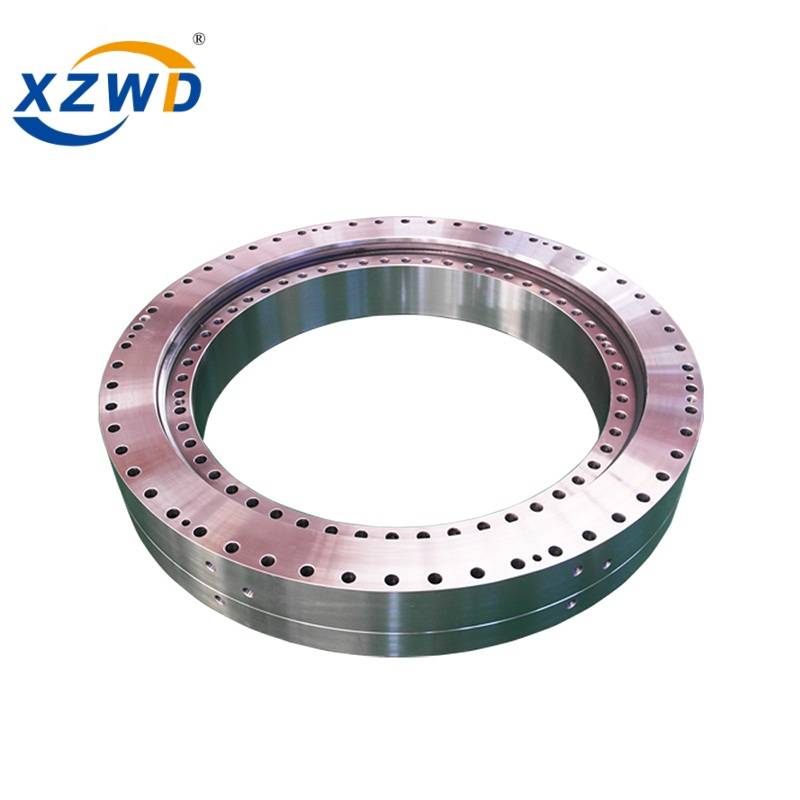

The slewing drive is a gearbox that can safely hold radial and axial loads, as well as transmit a torque for rotating. The rotation can be in a single axis,

or in multiple axes together. Slewing ring drives are made by manufacturing gearing, bearings, seals, housing, motor and other auxiliary components

and assembling them into a finished gearbox. The slewing drive uses precision kinematics to provide a large proportion of single-stage gearing.

Bearings and gears are assembled into a small, self-contained, and ready-to-install case to optimize weight and performance.

These highly adaptable products also feature robust shock resistance, long life performance, smooth rotation, bearing protection and sealed drive options.

As an experienced slew drive manufacturer, we have the capability to provide high quality slew drives.

| DIMENSIONS PARAMETER | |||||||||||||||||

| Model | External Dimensions | Installation Dimensions | Mounting Hole Date | ||||||||||||||

| L1 | L2 | L3 | H2 | D0 | D2 | D3 | D4 | D5 | n1 | M1 | T1 | T2 | n2 | M2 | T3 | T4 | |

| mm | Inner Ring | Outer Ring | |||||||||||||||

| SE3 | 190 | 160.5 | 80 | 109 | 152 | 100 | no | no | 100 | 6 | M10 | 17 | 32 | 6 | M10 | 22 | no |

| SE5 | 219.2 | 170.5 | 93.7 | 80 | 183 | 70 | 50 | 103.5 | 135 | (8-1) | M10 | 20 | 42 | 6 | M10 | 20 | 39 |

| SE7 | 295.7 | 186 | 132.7 | 83.8 | 258 | 120.6 | 98 | 163 | 203.2 | 10 | M12 | 25 | 47 | 8 | M12 | 25 | 43.4 |

| SE9 | 410.5 | 321.7 | 174.2 | 107.9 | 345 | 175 | 146 | 222.5 | 270 | (16-1) | M16 | 30 | 65.9 | 16 | M16 | 30 | 52 |

| SE12 | 499.5 | 339.5 | 220 | 110.4 | 431 | 259 | 229 | 314.3 | 358 | (20-1) | M16 | 30 | 69.4 | 18 | M16 | 30 | 51 |

| SE14 | 529.9 | 337.5 | 237.6 | 111 | 456.5 | 295 | 265 | 342.5 | 390 | (24-1) | M16 | 30 | 69 | 18 | M16 | 30 | 52 |

| SE17 | 621.8 | 385.2 | 282.6 | 126 | 550.5 | 365.1 | 324 | 422.1 | 479.4 | 20 | M16 | 32 | 79 | 20 | M16 | 32 | 55 |

| SE21 | 750.4 | 475 | 345 | 140 | 667.7 | 466.7 | 431.8 | 525.5 | 584.2 | (36-1) | M20 | 40 | 85 | 36 | M20 | 40 | no |

| SE25 | 862.8 | 469 | 401.8 | 130 | 792 | 565 | 512 | 620 | 675 | (36-1) | M20 | 40 | 87 | 36 | M20 | 40 | no |

| PERFORMANCE PARAMETERS | |||||||||||||||||

| Model | (MAX)kN.m Output Torque |

(MAX)kN.m Tilting Moment Torque |

KN Static Axial Load |

kN Static Radial Load |

(MAX)kN.m Dynamic Axial Load |

(MAX)kN.m Dynamic Radial Load |

(MAX)kN.m Holding Torque |

Gear Radio | Tracking Precision | Self-locking Gears | kg Weight |

||||||

| SE3 | 0.4 | 1.1 | 30 | 16.6 | 9.6 | 8.4 | 2 | 62:1 | ≤0.20° | Yes | 14 kg | ||||||

| SE5 | 0.6 | 3 | 45 | 22 | 14.4 | 11.1 | 5.5 | 62:1 | ≤0.20° | Yes | 13 kg | ||||||

| SE7 | 1.5 | 13.5 | 133 | 53 | 32 | 28 | 10.4 | 73:1 | ≤0.20° | Yes | 23 kg | ||||||

| SE9 | 6.5 | 33.9 | 338 | 135 | 81 | 71 | 38.7 | 61:1 | ≤0.20° | Yes | 50 kg | ||||||

| SE12 | 7.5 | 54.3 | 475 | 190 | 114 | 100 | 43 | 78:1 | ≤0.20° | Yes | 65 kg | ||||||

| SE14 | 8 | 67.8 | 555 | 222 | 133 | 117 | 48 | 85:1 | ≤0.20° | Yes | 70 kg | ||||||

| SE17 | 10 | 135.6 | 970 | 390 | 235 | 205 | 72.3 | 102:1 | ≤0.15° | Yes | 105 kg | ||||||

| SE21 | 15 | 203 | 1598 | 640 | 385 | 335 | 105.8 | 125:1 | ≤0.15° | Yes | 180 kg | ||||||

| SE25 | 18 | 271 | 2360 | 945 | 590 | 470 | 158.3 | 150:1 | ≤0.15° | Yes | 218 kg | ||||||

1.Professional product design and load calcalation;

2.Made with high-quality materials to ensure the mechanical properties

3.Total quality management from material, production processes to finished product;

4.Continuous improvement of comprehensive strength, 2 factories under operation and 1 factory under construction with over 230 employees, providing slewing bearings 5000sets/month, slewing drives 1000sets/month.

5.Strong technical and R & D capabilities with an experienced technical team and cooperation with China University of Mining and Technology, Northwestern Polytechnical University and Tsinghua University.

6.Rich export experience, products are exported to more than 60 countries and regions.

7.Professional supplier of marine slewing bearing.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value "unification, dedication, tolerance" for Free sample for Slewing Drive With Motor - XZWD Precision Solar tracking Slewing drive SE5 – Wanda , The product will supply to all over the world, such as: Swaziland, Cancun, Georgia, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!