Good quality Ferris Wheel Slewing Bearing - High quality China factory Supply Small Excavator Slewing Ring – Wanda

Good quality Ferris Wheel Slewing Bearing - High quality China factory Supply Small Excavator Slewing Ring – Wanda Detail:

The slewing bearing of the small excavator basically needs to be replaced every two to three years. Most of the reasons are tooth ring gear collapse. Large radius of gyration, long-term high load, and overload work, causing tooth ring gear collapse. The slewing ring quality problems occupying a small part.

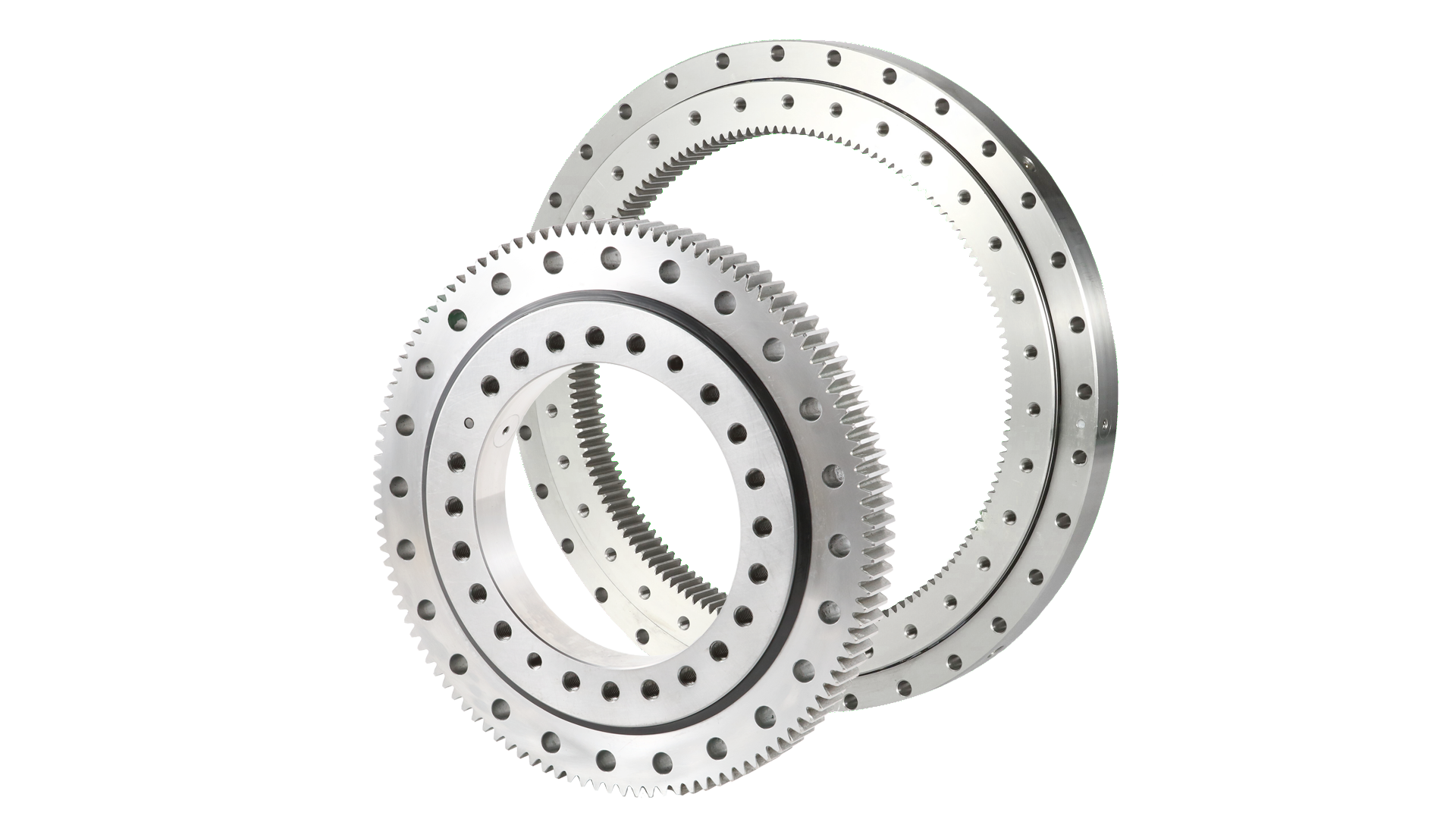

Slewing rotary bearings are widely used in construction machinery, it is the first and most widely used place of slewing rotary bearings, not only could be used for excavators, but also could be used for earthmoving machinery, dismantling machines, stackers and reclaimers, graders, roller, dynamic compactors, rock drilling machines, road headers and so on.

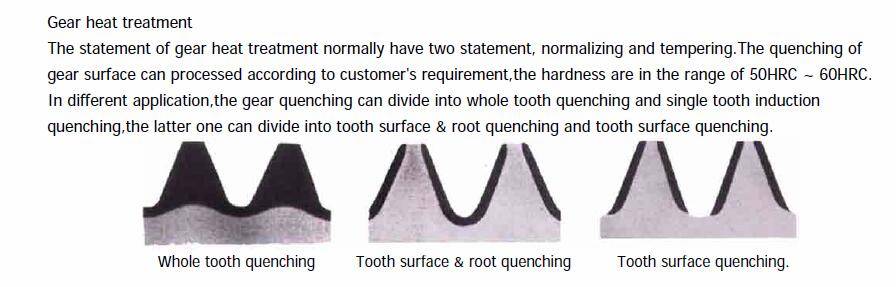

For the excavator, most using the internal gear slewing bearing with tooth quenched. The tooth quenched hardness is 50-60HRC.

Please see attached slewing bearing specification table to choose the suitable model you need for your excavator.

Xuzhou wanda slewing bearing co.,ltd is professional in produce varies slewing ring bearing for small excavators. The material for slewing bearing is quenched, and the tooth is hardened. If you have any demand, please contact us to get more details.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for Good quality Ferris Wheel Slewing Bearing - High quality China factory Supply Small Excavator Slewing Ring – Wanda , The product will supply to all over the world, such as: Manchester, Canberra, Ethiopia, Our company regards "reasonable prices, high quality,efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.