High quality slewing ring bearing for tower crane

Working principle of slewing bearing of tower crane

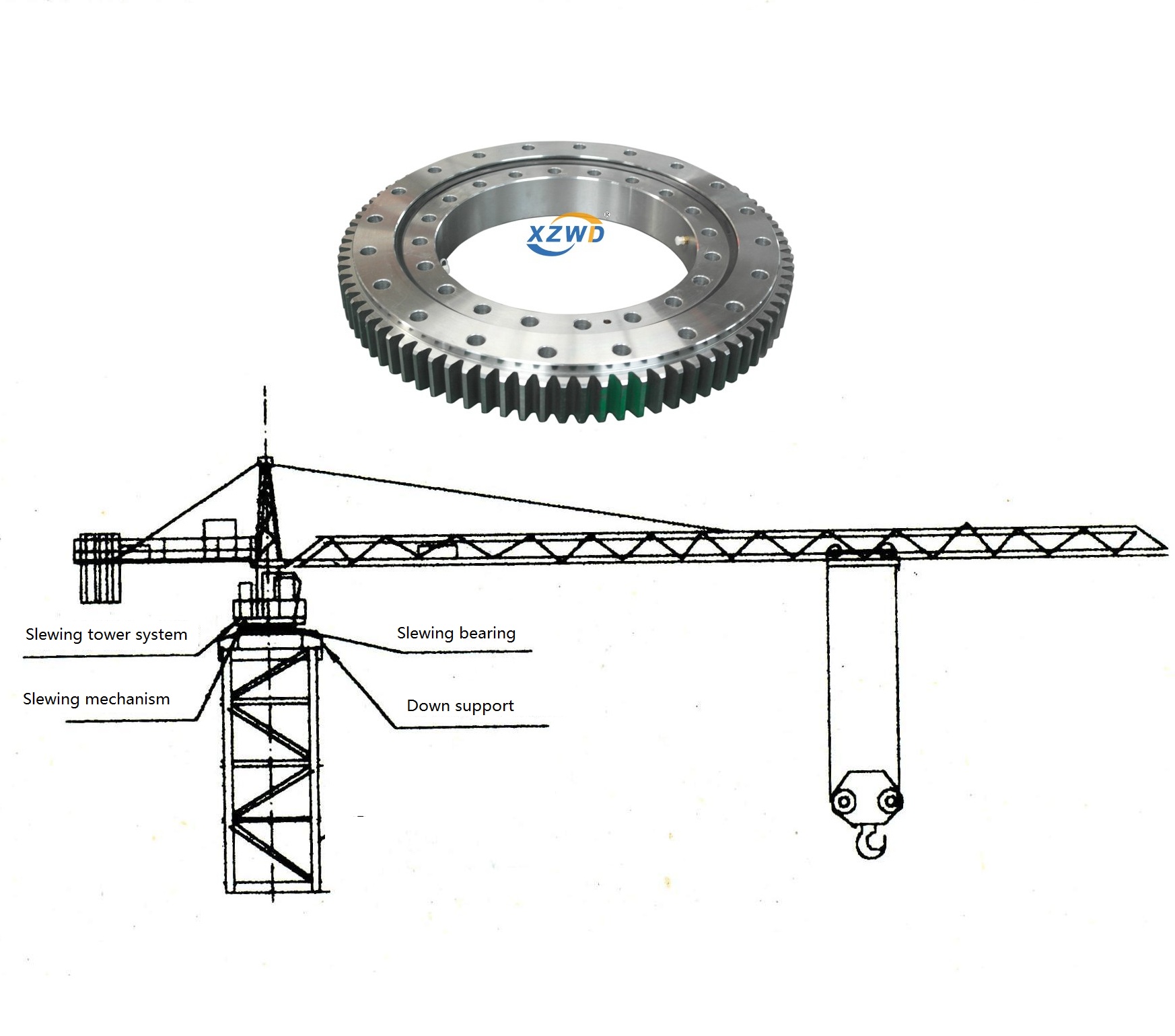

1. Tower crane implements tower slewing mechanism, which relies on boom slewing to ensure its working coverage.

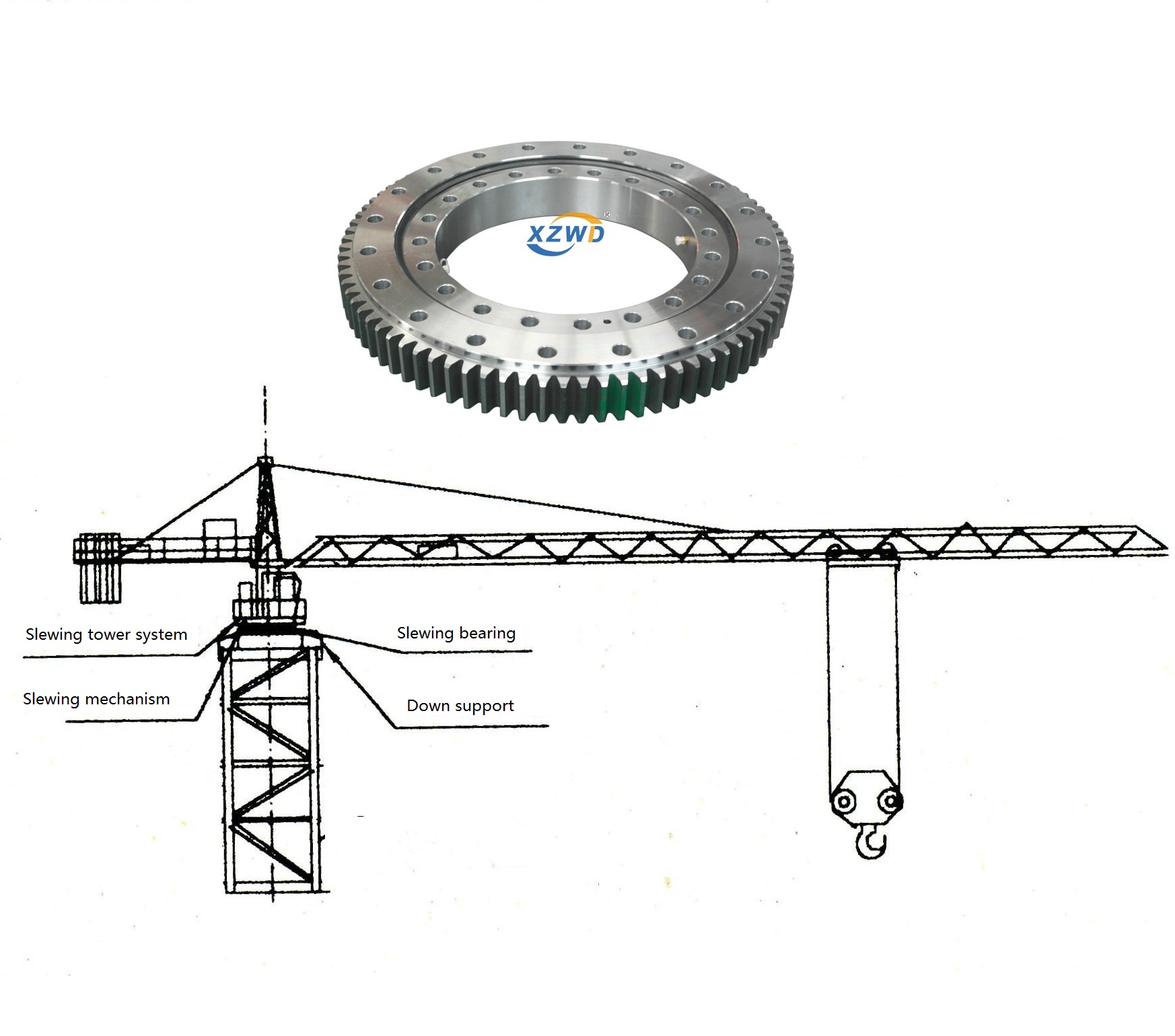

2. The rotation movement is produced by the upper and lower slewing bearings which are respectively installed on the inner and outer rings of the slewing bearing, and the pinion is driven by the slewing mechanism. The pinion is meshed with the big gear of the slewing bearing to drive the upper slewing bearing to move relative to the lower slewing bearing.

3. Generally, the slewing mechanism is composed of slewing motor, hydraulic coupling, planetary reducer and pinion. In addition, according to the needs, the slewing mechanism is equipped with limit torque limiter, slewing buffer device, slewing limiter and other safety devices.

4. In order to prevent the boom from sliding under the action of strong wind, the slewing mechanism is equipped with a stopper. But in the non working state, the slewing mechanism should allow the boom to rotate freely with the wind.

Generally, light and medium tower cranes are only equipped with one set of slewing mechanism. The heavy tower crane is equipped with two sets of slewing mechanism. Super heavy tower crane is equipped with 3 ~ 4 sets of slewing mechanism according to different lifting capacity and moment of inertia. The stable speed control system and pole changing motor are adopted, which can start and brake smoothly.

XZWD slewing bearing Co., Ltd. is a manufacturer specializing in the production of various engineering machinery slewing bearings. It is located in Xuzhou City, Jiangsu Province, the capital of China’s construction machinery, in the same city as XCMG Group. We are very knowledgeable about construction machinery and can provide the most suitable solutions for the majority of factory machinery users. If you have any needs, please contact us.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.