Low price for Gear Bearing - Non gear slewing ring bearing 010 series with competitive price – Wanda

Low price for Gear Bearing - Non gear slewing ring bearing 010 series with competitive price – Wanda Detail:

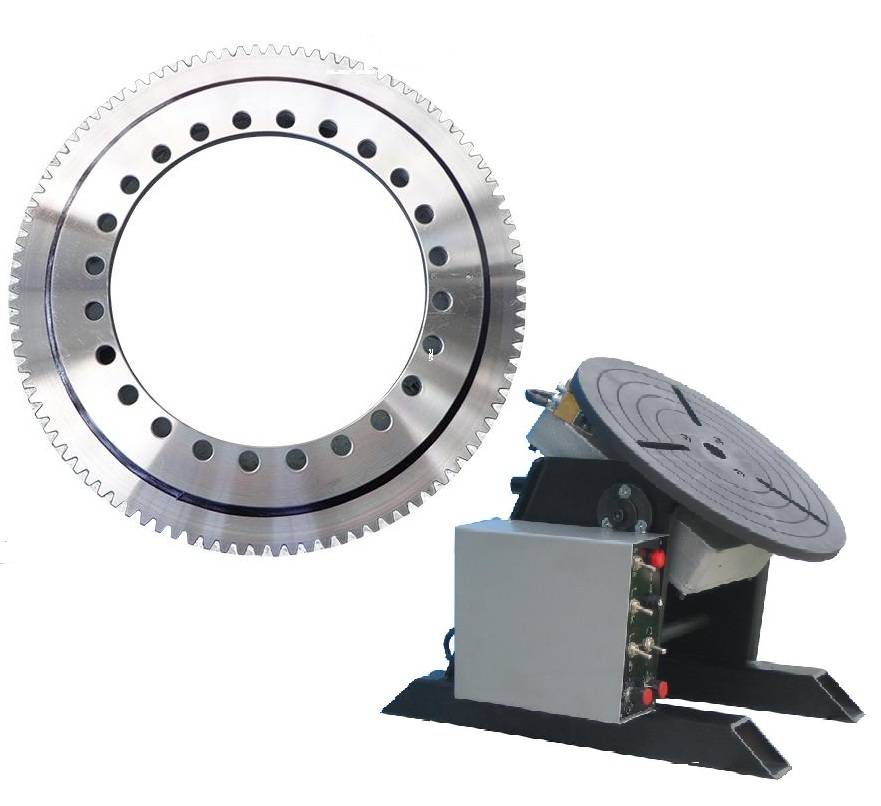

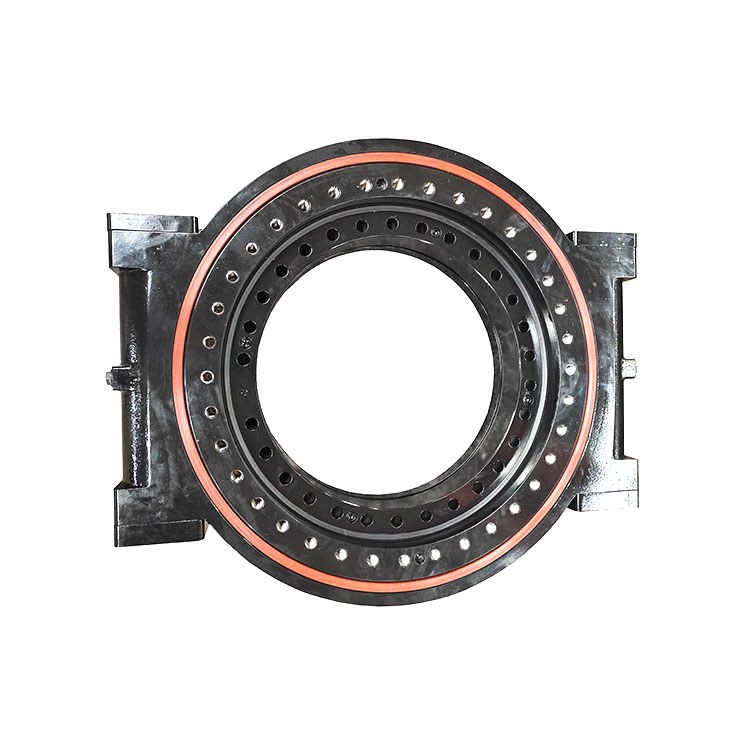

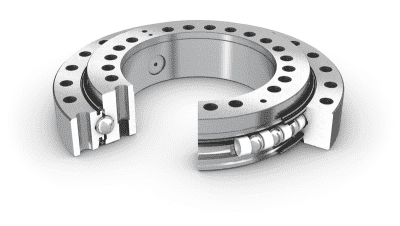

The four-point contact ball slewing bearing has a high static load capacity and can provide smooth rotation. The toothless four-point contact ball slewing bearing has the advantages of high transmission efficiency, reliable work, and simple and compact structure. There are raceways in the inner and outer rings, and the inner and outer rings are connected by steel balls. The inner and outer rings are equipped with mounting holes, which can be fixed on the corresponding tooling with bolts, and the inner ring can be rotated, or the outer ring can be rotated as needed, or the inner and outer rings can be rotated at the same time.

Slewing bearings generally use 50Mn or 42CrMo as raw materials. The nature and quality of the raw materials have a great impact on the performance and service life of the slewing bearing. XZWD slewing bearings only use materials from qualified suppliers. We will conduct strict inspections on forgings, including ultrasonic inspection, hardness inspection and metallographic inspection.

50Mn is a high-quality carbon structural steel. It has high strength, elasticity and hardness, and is often used after quenching and tempering. 50Mn has poor welding performance, and has a tendency to overheat sensitivity and temper brittleness. 50Mn is usually used to manufacture parts with higher requirements for wear resistance and load capacity, such as gears and gear shafts.

42CrMo material is an alloy steel, very suitable for forging processing. It has high strength, high hardenability and good toughness. The deformation of 42CrMo during quenching is very small, and it has high creep strength and durability under high temperature. Compared with 50Mn, 42CrMo has better fatigue strength, but the cost is higher.

Please find below specification for the non gear slewing ring:

| No | Model | Dimensions(mm) | Mounting Dimensions | Structural Dimensions(mm) | Weight(kg) | |||||||||||

| D | d | H | D1 | D2 | n | Φ | dm | L | n1 | D3 | d1 | H1 | h | |||

| 1 | 010.20.200 | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 28 | 2 | 201 | 199 | 50 | 10 | 20 |

| 2 | 010.20.224 | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 28 | 2 | 225 | 223 | 50 | 10 | 22 |

| 3 | 010.20.250 | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 28 | 2 | 251 | 249 | 50 | 10 | 25 |

| 4 | 010.20.280 | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 28 | 2 | 281 | 279 | 50 | 10 | 28 |

| 5 | 010.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 44 |

| 6 | 010.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 49 |

| 7 | 010.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 56 |

| 8 | 010.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 62 |

| 9 | 010.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 498 | 70 | 10 | 85 |

| 10 | 010.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 558 | 70 | 10 | 95 |

| 11 | 010.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 628 | 70 | 10 | 110 |

| 12 | 010.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 708 | 70 | 10 | 120 |

| 13 | 010.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 220 |

| 14 | 010.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 240 |

| 15 | 010.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 270 |

| 16 | 010.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 300 |

| 17 | 010.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1252 | 1248 | 100 | 10 | 420 |

| 18 | 010.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1402 | 1398 | 100 | 10 | 480 |

| 19 | 010.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1602 | 1598 | 100 | 10 | 550 |

| 20 | 010.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1802 | 1798 | 100 | 10 | 610 |

| 21 | 010.40/60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2002 | 1998 | 132 | 12 | 1100 |

| 22 | 010.40/60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2242 | 2238 | 132 | 12 | 1250 |

| 23 | 010.40/60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2502 | 2498 | 132 | 12 | 1400 |

| 24 | 010.40/60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 1600 |

| 25 | 010.50/75.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 2800 |

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Low price for Gear Bearing - Non gear slewing ring bearing 010 series with competitive price – Wanda , The product will supply to all over the world, such as: Congo, French, Pakistan, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!