Manufactur standard Cross Roller Slewing Bearing - High quality slewing bearing for aerial work platform(AWP) – Wanda

Manufactur standard Cross Roller Slewing Bearing - High quality slewing bearing for aerial work platform(AWP) – Wanda Detail:

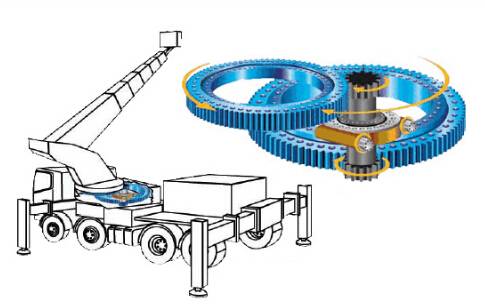

An aerial work platform (AWP), also known as an aerial device, elevating work platform (EWP), bucket truck or mobile elevating work platform (MEWP) is a mechanical device used to provide temporary access for people or equipment to inaccessible areas.The aerial work platform’s lightweight and compact size makes it convenient to use in schools, churches, warehouses and more.  The aerial work platform are usually use slewing bearing, and the forward and reverse directions can be selected according to the needs of the operation. The slewing part of the slewing mechanism and the work platform are both installed on the slewing support.

The aerial work platform are usually use slewing bearing, and the forward and reverse directions can be selected according to the needs of the operation. The slewing part of the slewing mechanism and the work platform are both installed on the slewing support.

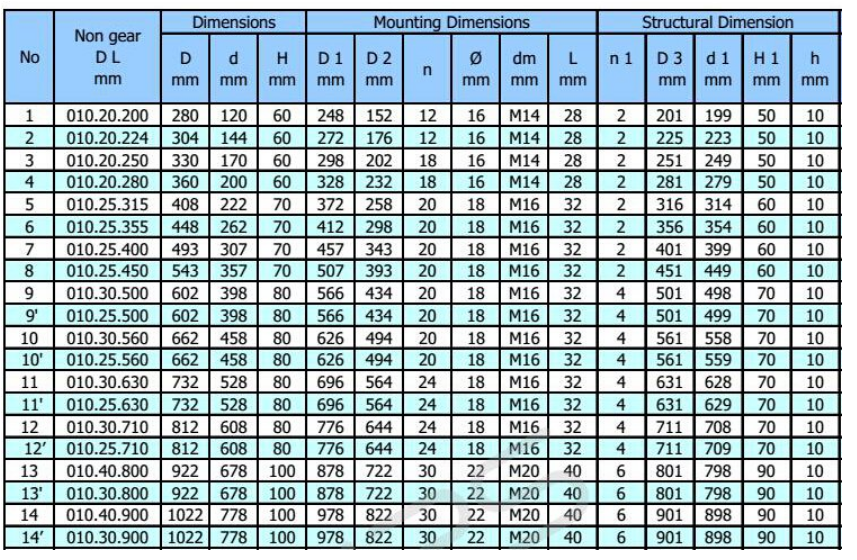

It is mainly use the single row four point slewing bearing, you can see the catalogue as following:

.

.

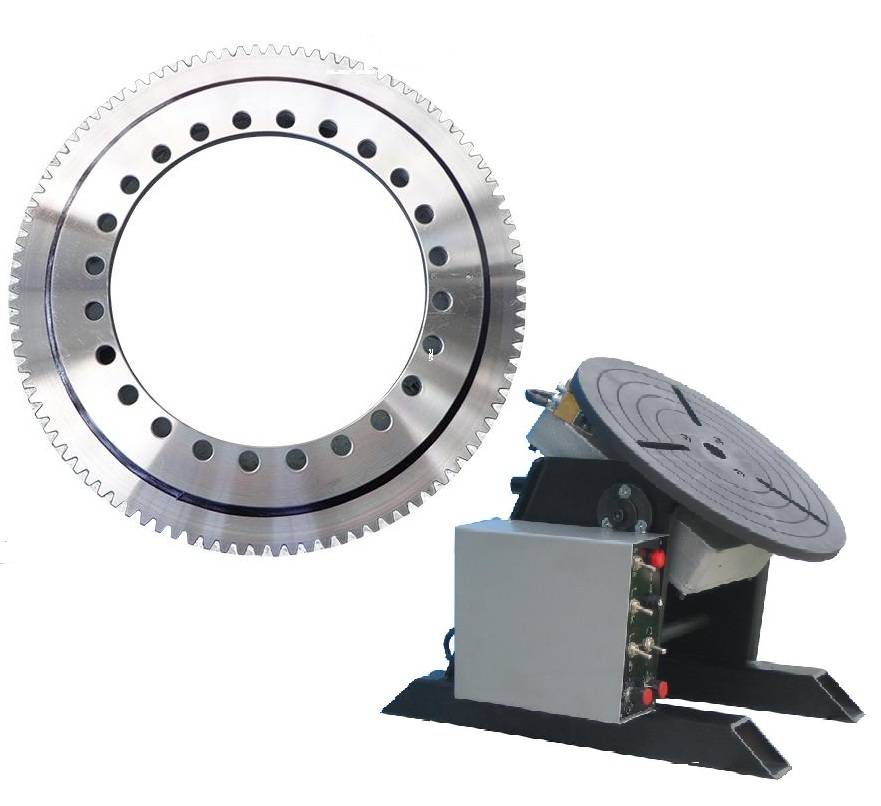

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

We stick with the theory of "quality first, company first, steady improvement and innovation to satisfy the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our provider, we deliver the items together with the fantastic good quality at the reasonable value for Manufactur standard Cross Roller Slewing Bearing - High quality slewing bearing for aerial work platform(AWP) – Wanda , The product will supply to all over the world, such as: Argentina, Los Angeles, French, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!