Manufactur standard Cross Roller Slewing Bearing - single row ball turntable slewing ring bearing with external gear – Wanda

Manufactur standard Cross Roller Slewing Bearing - single row ball turntable slewing ring bearing with external gear – Wanda Detail:

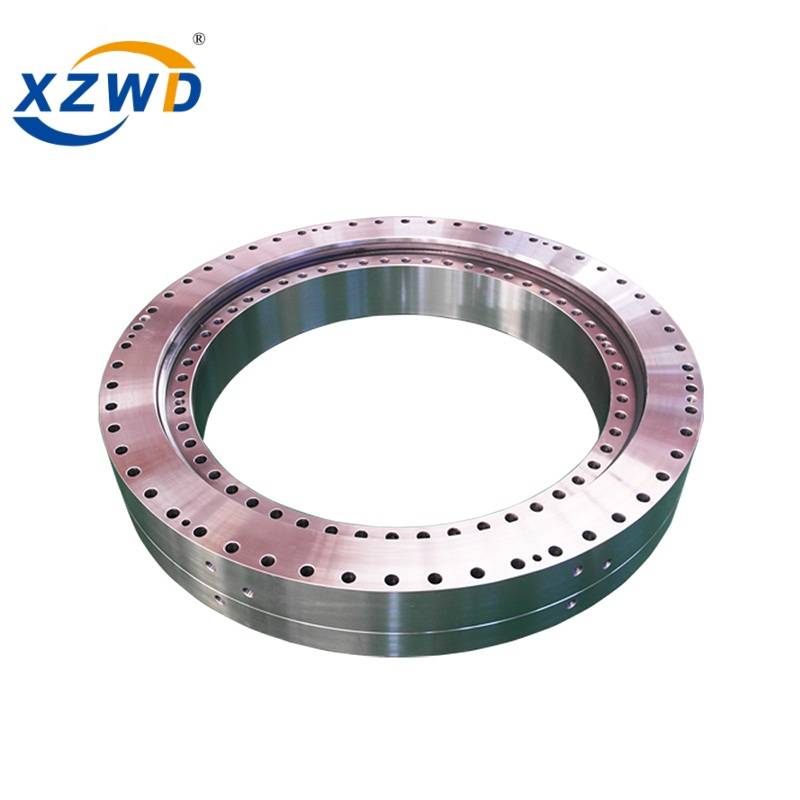

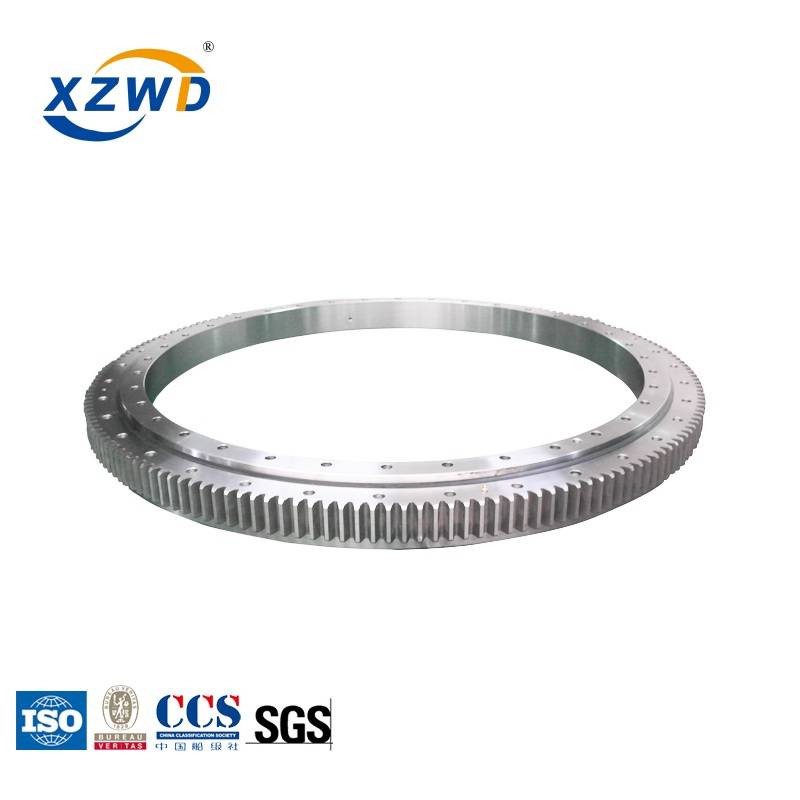

we are composed of 2 seat rings.It features compact in design,and light in weight.The balls contact with the circular race at four points,via which the axial force,radial force and resultant moment may be born simultaneously.

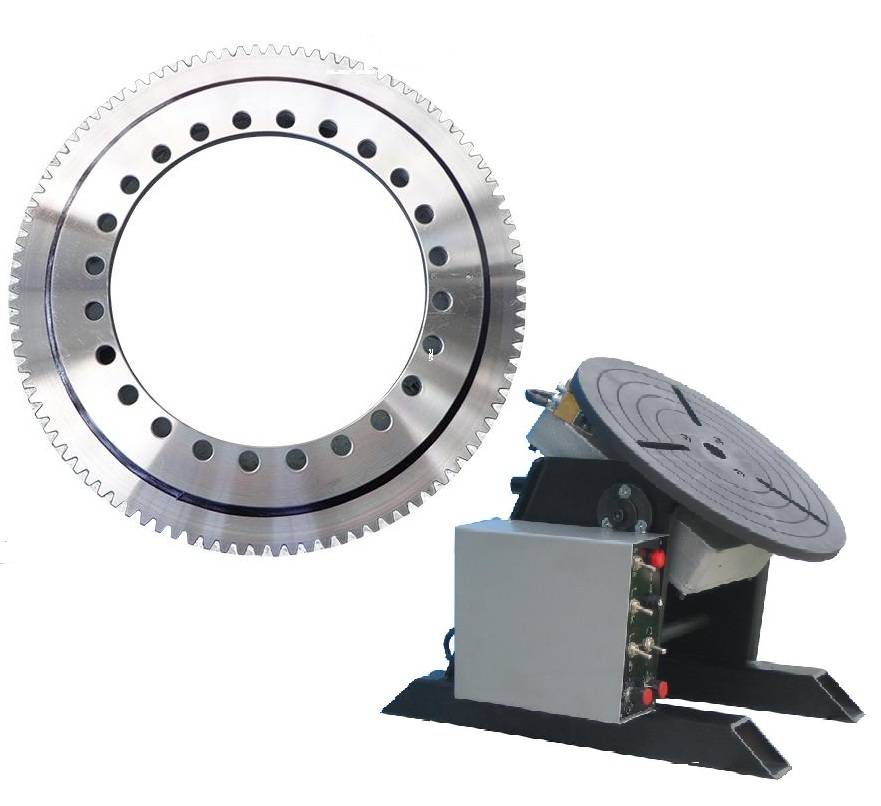

It may be used for slewing conveyer, welding arms and positioners,light,medium duty cranes,excavators and other engineering machines.

Product available including: Single and Double Row Ball, Three Row Roller, Cross Roller Sealed and Unsealed Internal Geared, External Geared and Non-Geared Clearance or Preloaded

We have strict production schedule to assure the delivery time, the production schedule as below:

A. Forging purchase period: 15-20 days

B. Production process:

1. Rough turning: 2-3 days

2. Raceway heat treatment: 2 days

3. Fine turning: 2 days

4. Gear cutting: 4-5 days

5. Drilling: 2-3 days

6. Final turning: 2 days

7. Assembling and Inspection: 2 days

C. Packing and delivery to Port: 3-5 days

Totally about 40-50days

The products are widely used in engineering machinery, building machinery, metallurgical and mining machinery,shipping port machinery, environmental protection machinery, light industry machinery, petroleum chemical machinery,engineering vehicle, war industry equipment and so on.

Turntable and Slewing Ring bearings utilize one to three rows of balls or rollers in order to provide smooth rotation even under extremely large loads. In addition to radial and axial loads, these bearings are able to support large moments in situations when loads are cantilevered away from the bearing’s central axis.

Turntables and Slewing Rings are offered in both metric and inch sizes with the ability to customize the mounting interfaces to suite your application. What differentiates Slewing Rings from Turntables is the inclusion of gear teeth on either the inner or outer rings.

We focus and control every production detail,Only for the delivery of good products to customers.

The material of the slewing bearing are generally high alloy-structural steels,such as 42CrMo,50Mn.

The material of rolling body is GCr15 and it is purchased from domestic suppliers with highest quality.

| No | External gear | Dimensions (mm) | Mounting Dimensions (mm) | Structural Dimension (mm) | Gear data | Gear force10^4 KN | weight kg |

||||||||||||||||

| D | d | H | D1 | D2 | n | Φ | dm | L | n1 | D3 | d1 | H1 | h | b | x | M | De | z | N | T | |||

| 1 | 011.20.200 | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 28 | 2 | 201 | 199 | 50 | 10 | 40 | 0 | 3 | 300 | 98 | 1.5 | 2.1 | 24 |

| 2 | 011.20.224 | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 28 | 2 | 225 | 223 | 50 | 10 | 40 | 0 | 3 | 321 | 105 | 1.5 | 2.1 | 25 |

| 3 | 011.20.250 | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 28 | 2 | 251 | 249 | 50 | 10 | 40 | 0 | 4 | 352 | 86 | 2.1 | 2.8 | 30 |

| 4 | 011.20.280 | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 28 | 2 | 281 | 279 | 50 | 10 | 40 | 0 | 4 | 384 | 94 | 1.5 | 2.8 | 34 |

| 5 | 011.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 50 | 0 | 5 | 435 | 85 | 2.9 | 4.4 | 52 |

| 6 | 011.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 50 | 0 | 5 | 475 | 93 | 2.9 | 4.4 | 59 |

| 7 | 011.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 50 | 0 | 6 | 528 | 86 | 3.5 | 5.3 | 69 |

| 8 | 011.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 50 | 0 | 6 | 576 | 94 | 3.5 | 5.3 | 76 |

| 9 | 011.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 499 498 | 70 | 10 | 60 | 0.5 | 5 | 629 | 123 | 3.7 | 5.2 | 85 |

| 012.30.500 | 6 | 628.8 | 102 | 4.5 | 6.2 | ||||||||||||||||||

| 10 | 011.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 559 558 | 70 | 10 | 60 | 0.5 | 5 | 689 | 135 | 3.7 | 5.2 | 95 |

| 012.25/30.560 | 6 | 688.8 | 112 | 4.5 | 6.2 | ||||||||||||||||||

| 11 | 011.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 629 628 | 70 | 10 | 60 | 0.5 | 6 | 772.8 | 126 | 4.5 | 6.2 | 110 |

| 012.25/30.630 | 8 | 774.4 | 94 | 6 | 8.3/8.2 | ||||||||||||||||||

| 12 | 011.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 709 708 | 70 | 10 | 60 | 0.5 | 6 | 850.8 | 139 | 4.5 | 6.2 | 120 |

| 012.30.710 | 8 | 854.4 | 104 | 6 | 8.9/8.3 | ||||||||||||||||||

| 13 | 011.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 80 | 0.5 | 8 | 966.4 | 118 | 8 | 11.1 | 220 |

| 012.40.800 | 10 | 968 | 94 | 10 | 14.1/14 | ||||||||||||||||||

| 14 | 011.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 80 | 0.5 | 8 | 1062.4 | 130 | 8 | 11.1 | 240 |

| 012.40.900 | 10 | 1068 | 104 | 10 | 14 | ||||||||||||||||||

| 15 | 011.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 80 | 0.5 | 10 | 1188 | 116 | 10 | 14 | 270 |

| 012.30/40.1000 | 12 | 1185.6 | 96 | 12 | 16.7 | ||||||||||||||||||

| 16 | 011.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 80 | 0.5 | 10 | 1298 | 127 | 10 | 14 | 300 |

| 012.30/40.1120 | 12 | 1305.6 | 106 | 12 | 16.7 | ||||||||||||||||||

| 17 | 011.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1252 | 1248 | 100 | 10 | 90 | 0.5 | 12 | 1449.6 | 118 | 13.5 | 18.8 | 420 |

| 012.35/45.1250 | 14 | 1453.2 | 101 | 15.8 | 21.9 | ||||||||||||||||||

| 18 | 011.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1402 | 1398 | 100 | 10 | 90 | 0.5 | 12 | 1605.6 | 131 | 13.5 | 18.8 | 480 |

| 012.35/45.1400 | 14 | 1607.2 | 112 | 15.5 | 21.9 | ||||||||||||||||||

| 19 | 011.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1602 | 1598 | 100 | 10 | 90 | 0.5 | 14 | 1817.2 | 127 | 15.8 | 21.9 | 550 |

| 012.35/45.1600 | 16 | 1820.8 | 111 | 18.1 | 25 | ||||||||||||||||||

| 20 | 011.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1801 1802 |

1798 | 100 | 10 | 90 | 0.5 | 14 | 2013.2 | 141 | 15.8 | 21.9 | 610 |

| 012.35/45.1800 | 16 | 2012.8 | 123 | 18.1 | 25 | ||||||||||||||||||

| 21 | 011.40/60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2001 2002 |

1998 | 132 | 12 | 120 | 0.5 | 16 | 2268.8 | 139 | 24.1 | 33.3 | 1100 |

| 012.40/60.2000 | 18 | 2264.4 | 123 | 27.1 | 37.5 | ||||||||||||||||||

| 22 | 011.40/60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2241 2242 |

2238 | 132 | 12 | 120 | 0.5 | 16 | 2492.8 | 153 | 24.1 | 33.3 | 1250 |

| 012.40/60.2240 | 18 | 2498.4 | 136 | 27.1 | 37.5 | ||||||||||||||||||

| 23 | 011.40/60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2501 2502 |

2498 | 132 | 12 | 120 | 0.5 | 18 | 2768.4 | 151 | 27.1 | 37.5 | 1400 |

| 012.40/60.2500 | 20 | 2776 | 136 | 30.1 | 41.8 | ||||||||||||||||||

| 24 | 011.40/60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 120 | 0.5 | 18 | 3074.4 | 168 | 27.1 | 37.5 | 1600 |

| 012.40/60.2800 | 20 | 3076 | 151 | 30.1 | 41.8 | ||||||||||||||||||

| 25 | 011.50/75.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 150 | 0.5 | 20 | 3476 | 171 | 37.7 | 52.2 | 2800 |

| 012.50/75.3150 | 22 | 3471.6 | 155 | 41.5 | 57.4 | ||||||||||||||||||

Note:

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2.The Oil nipple’s location can be change according to the user’s application.

2. n-φcan change to tapped hole,the diameter of tapped hole is M,depth is 2M.

3. The tangential tooth force in the form is the max tooth force,the nominal tangential tooth force is 1/2 of the max one.

4. “K” is addendum reduction coefficient.

XZWD is a slewing bearing manufacturer specializing in standard and non-standard slewing bearing.Over the years, we supplied high quality product & good service to every user and gain good credit.We have strict quality control system in our own factory,meanwhile, we have passed ISO9001-2008 Quality System Certification and JG/T66-1999, JG/T67-1999, JG/T68-1999, JB/T2300-1999 with our country’s engineering & machinery standards.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for Manufactur standard Cross Roller Slewing Bearing - single row ball turntable slewing ring bearing with external gear – Wanda , The product will supply to all over the world, such as: UK, Casablanca, Madras, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we've been likely to be pleased to serve you.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.