Manufactur standard Cross Roller Slewing Bearing - Three row roller Slewing bearing with heavy load for wheeled crane – Wanda

Manufactur standard Cross Roller Slewing Bearing - Three row roller Slewing bearing with heavy load for wheeled crane – Wanda Detail:

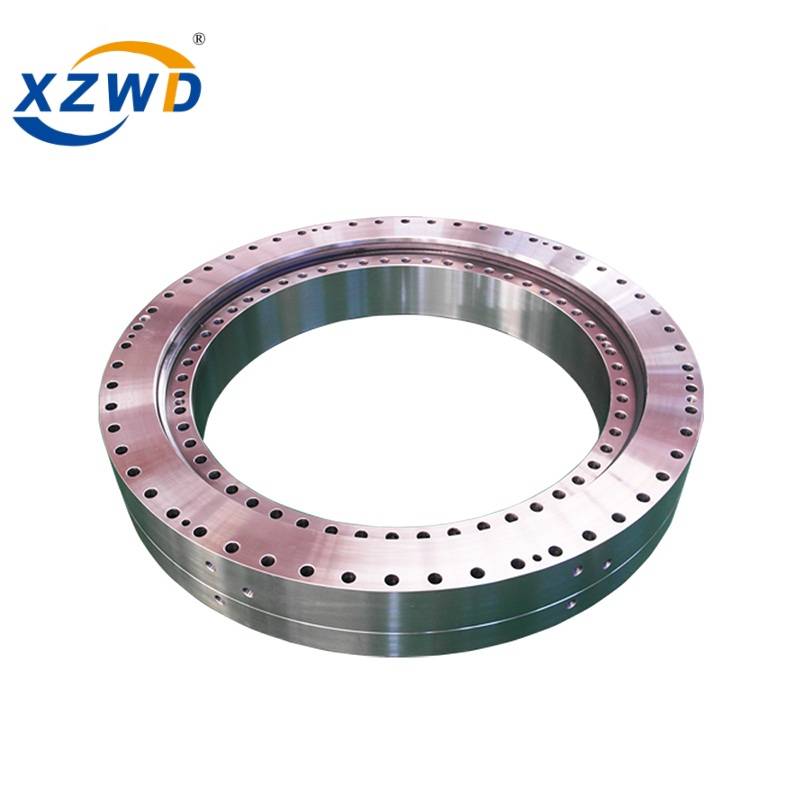

China top manufacturer high quality heavy load three row roller slewing bearing

Wheeled crane consists of two parts: upper part and lower part. Up part is the lifting operation part, equipped with boom, hoisting mechanism, luffing mechanism, counterweight and turntable, etc.; lower part is the supporting and walking part. Slewing bearing connection between upper and lower cars.

The wheeled crane offer use three row roller slewing bearing.Three rings are separated so each row roller loads can be confirmed exactly and they can bear axial force, resultant torque and considerable radial force at the same time. This series has the maximum load capacity.

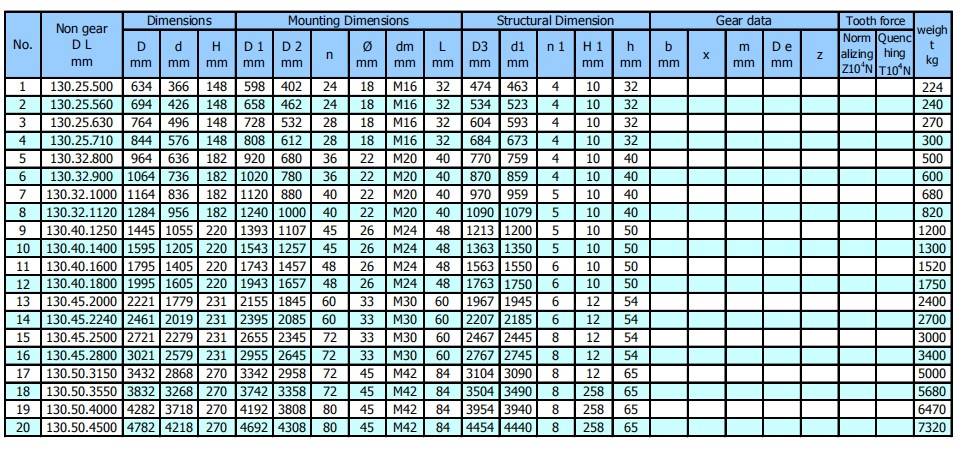

You can see the attached catalogue for the slewing bearing. Anyone you are interesting, you can contact us!

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Manufactur standard Cross Roller Slewing Bearing - Three row roller Slewing bearing with heavy load for wheeled crane – Wanda , The product will supply to all over the world, such as: Czech, Portugal, Hungary, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.