Manufacturer for Slewing Bearing For Excavator - Flange Type Light Slewing Bearing For Rotating Platform – Wanda

Manufacturer for Slewing Bearing For Excavator - Flange Type Light Slewing Bearing For Rotating Platform – Wanda Detail:

Aerial work vehicles are very common special vehicles. The use is very common.

The working principle of the slewing bearing on the aerial work vehicle Slewing mechanism.

The vehicle-mounted aerial work vehicle usually adopts a full-slewing slewing mechanism, and the forward and reverse directions can be selected according to the needs of the operation. Both the slewing part of the slewing mechanism and the work platform are installed on the slewing bearing.

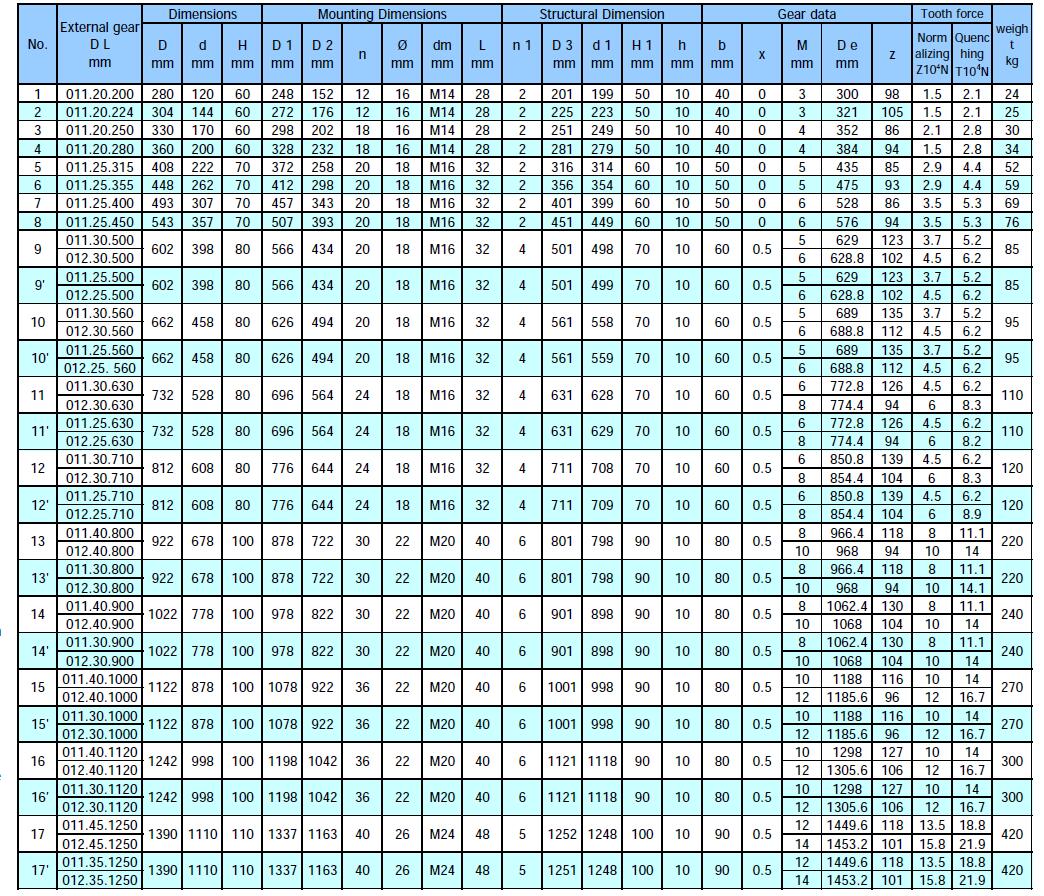

Model and detailed parameter table of slewing bearing suitable for aerial work vehicles.

XZWD Slewing Bearing Co.,Ltd is the professional manufacturer for variety slewing bearings. For lamp aerial work vehicles, normally adopt the 01 series external gear type, 11 series external gear type, QN series, depending on the arm length and size of the higher operating vehicle, the size of each series of slewing ring is also different! The specific selection model is determined according to the specific vehicle model.

From the perspective of the international market situation, in order to seek new economic growth points, foreign street lamp maintenance and high-altitude vehicle companies will actively explore the domestic market and occupy an absolute advantage in mid-to-high-end products. Joint ventures and cooperation will contribute to the promotion of high-value-added products in my country. The development of it has played a positive role. At the same time, as the government intensifies the reform of state-owned enterprises, the privatization rate of the street lamp maintenance and aerial vehicle industry will increase to more than 80%.

If you need the slewing ring bearings for lamp maintenance aerial vehicle, just feel free to contact me!

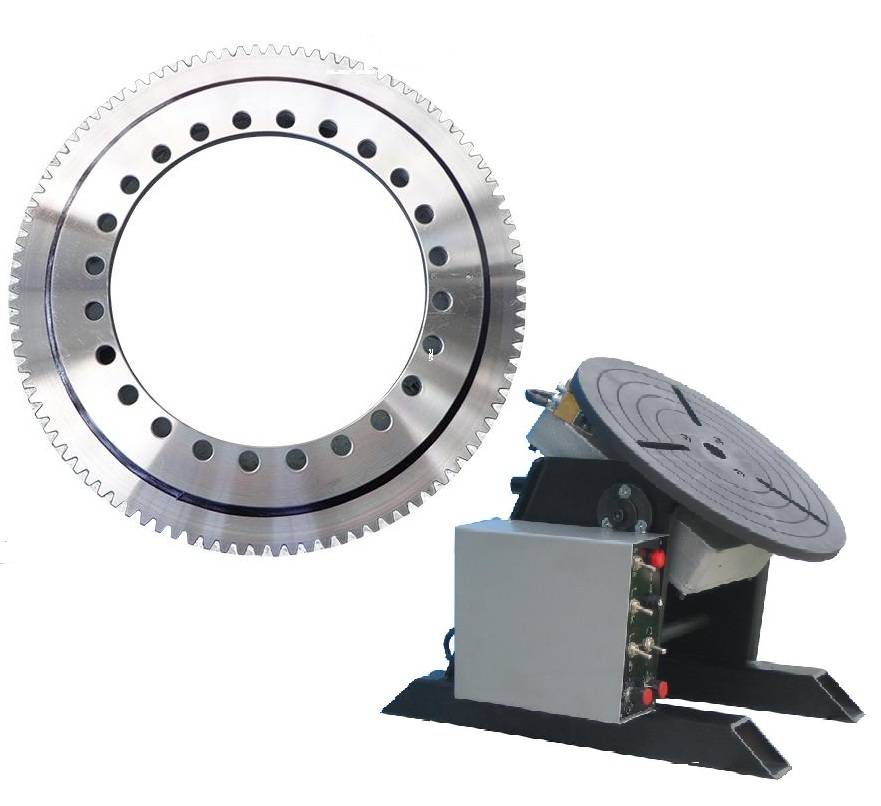

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for Manufacturer for Slewing Bearing For Excavator - Flange Type Light Slewing Bearing For Rotating Platform – Wanda , The product will supply to all over the world, such as: Swiss, Chile, Manila, Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.