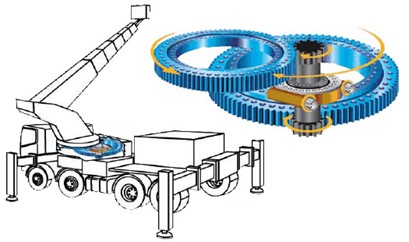

Double worm slewing drive is a brand new slewing drive product, which consists of outer casing, worm gear ring, worm, motor and other components. Compared with the single worm slewing drive, the double worm slewing drive still has the characteristics of modularization, safety and simplified host design. The load capacity is better and the output torque far exceeds that of a single worm rotary drive. The double worm slewing drive abandons the core component slewing bearing in design, and forms a double-row space cross-roller slewing bearing in theory through the outer casing and the worm gear contained within it. Rotation to ensure that while achieving higher bearing capacity, it can also generate larger output torque. Due to the extremely complex manufacturing process of this kind of slewing drive, there are not many manufacturers in the industry that can produce this kind of special slewing drive, and only Anshan, Liaoning, has such a special slewing drive manufacturer in China.

Application fields of double worm slewing drive

1. Compared with the single worm slewing drive, the double worm slewing drive is more suitable for the steering device of the heavy-duty flatbed transporter. Practice has proved that when the single worm slewing drive is used for heavy equipment with a larger tonnage , it will produce jitter, noise, casing distortion and even worm breakage. Therefore, this special rotary drive has become a supporting product favored by the majority of heavy equipment designers.

2. Heavy lifting and aerial work

In the application field with extremely high demands on load and torque, the advantages of single worm slewing drive are gradually lost. Double worm slewing drive caters to the needs of the majority of users, and has extremely strong adaptability to harsh working conditions and use conditions, especially In the field of heavy lifting and heavy-duty aerial work, the double worm slewing drive is used together with the traditional slewing bearing, which makes the slewing mechanism even more powerful. While obtaining a larger reduction ratio, it also provides an output torque several times higher than the traditional design.

3. Heavy gantry lifting equipment

Most of the traditional gantry cranes are rail-moving type, which can only move linearly and parallelly on limited rails. At present, some companies that pay more attention to technological innovation have gradually realized that it is imperative to break the traditional design concept of gantry lifting equipment. The double worm slewing drive is selected as the gantry hoisting equipment for the steering system. Compared with the previous design, the required hoisting equipment per unit operating area is reduced by 75%. While reducing operating costs and maintenance costs, The work efficiency has also been greatly improved.

4. Rotary table and mixing machinery field

Taking the concrete mixing machine as an example, while realizing the rotary mixing, the steering equipment is often required to provide a larger output torque. The double worm slewing drive is selected, which simplifies the design of the main engine and the slewing mechanism while achieving a larger output torque. The high assembly accuracy of the double worm rotary drive (mainly the backlash of the worm gear pair) is also one of the reasons why many users use the product for the worktable steering gear of large-scale high-precision equipment.

Post time: May-07-2022