More and more people are using slewing bearings, but most of them don’t know what aspects need to be paid attention to in use. Today, our Xuzhou Wanda slewing bearing gives a few precautions.

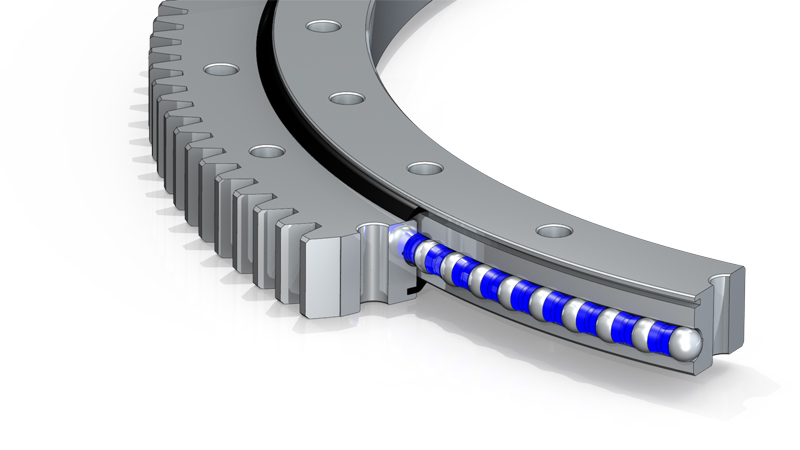

1. Regularly add grease

The slewing bearing should be regularly filled with grease. According to different types of slewing bearings, the filling time is also different.

Ball type: add grease every 100 hours of operation;

Roller type: add grease every 50 hours of operation;

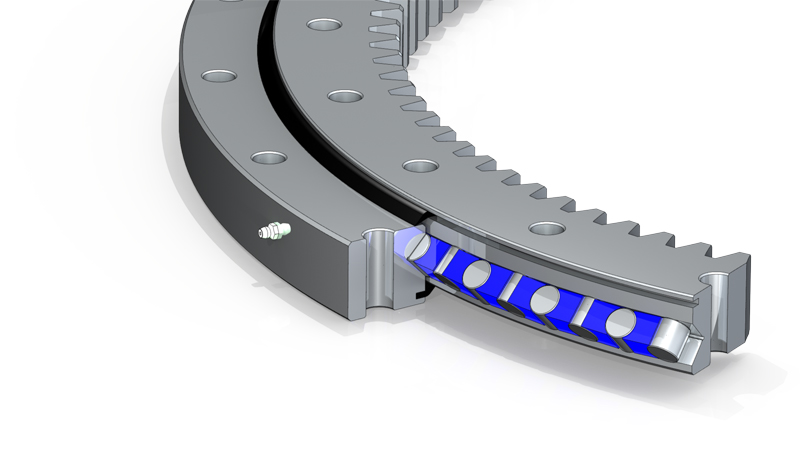

2. Cleaning and Inspection

During use, the sundries on the surface of the slewing bearing should be removed frequently. After the slewing bearing has been operated for 100 hours since its installation, the pre-tightening force of the bolts should be checked. After every 500 hours of operation, the check must be maintained with sufficient effort. It is also necessary to check whether the sealing strip of the slewing bearing is aging, cracked, damaged or detached. If one of these situations occurs, the sealing strip should be replaced in time to prevent the loss of sundries and grease in the raceway, and the corresponding grease should be applied after replacement. , to prevent the rolling elements and raceways from getting stuck or corroded.

3. Find faults and eliminate them in time

In use, pay close attention to the operation of the slewing bearing. If noise, impact, or sudden increase in power is found, it should be stopped immediately for inspection until all faults are eliminated. If necessary, it needs to be disassembled and inspected.

4. Do not touch water

When the slewing bearing is in use, it is forbidden to directly wash the slewing bearing with water to prevent water from entering the raceway and cause rust; strictly prevent hard foreign objects from approaching or entering the meshing area, so as to avoid injury to the teeth or unnecessary trouble.

If you meet any problem when use slewing bearing, you can contact us Xuzhou Wanda slewing bearing co.,ltd freely.

Post time: Sep-19-2022