Slewing ring bearing has been widely used in the market. Many people buy slewing bearings to use. But many people don’t know how to maintain them in the process of use. As a professional slewing bearing manufacturer - XZWD Slewing Bearing Co., Ltd.we will give you a detailed explanation today.

1、Receiving the product to be activated should be filled with new grease again according to different working conditions. The grease we suggest is No.2 extreme pressure lithium grease.

2、Slewing bearing should be filled with grease regularly, according to different types of slewing bearing, the specific grease filling time is as follows.

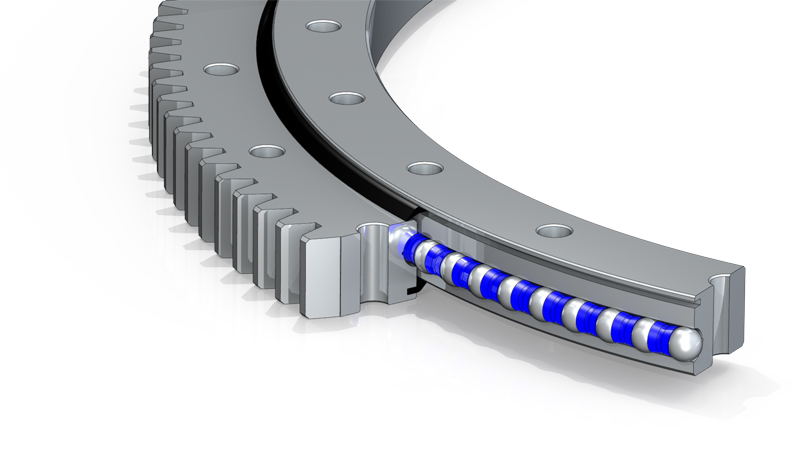

a: ball type: every 100 hours of operation to refill a grease.

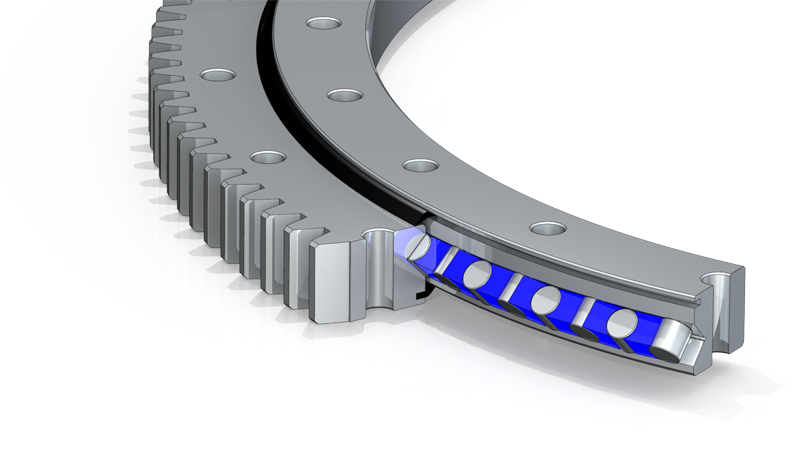

b: roller type: every 50 hours of operation to refill a grease.

If in the special working environment, such as: tropical, high temperature, dusty, temperature in and continuous continuous work, should shorten the grease refilling cycle, should ensure that every 50 hours of work refilling; gears should ensure that every 150 hours of work when working normally to apply detergent once, when working intensely, should every 75 hours of work to apply detergent once, note that the teeth must be wiped clean before applying detergent. The machine must also be refilled with new grease before and after a long period of stagnant operation, each filling must be filled with grease until it overflows from the sealing device, when filling grease, slowly transfer the rotary bearing, so that the grease in the raceway is filled evenly.

3、During use, the sundries on the surface of slewing bearing shall be removed frequently, and whether the sealing strip of slewing bearing is aged, cracked, damaged or detached shall be inspected. If one of the situations occurs, the sealing strip shall be replaced in time to prevent the loss of sundries and grease in the raceway. After replacement, the corresponding grease shall be applied to avoid the galling, jamming or corrosion of rolling element and raceway.

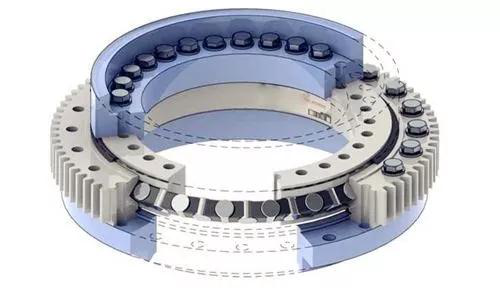

4、Slewing bearing since installation, the first time after 100 hours of operation, should check the bolt preload, after every 500 hours of operation to check once, must maintain sufficient preload.

5、After 2000 hours of cumulative work, if a bolt is found to be loose to less than 80% of the specified torque, the bolt and the two adjacent bolts are replaced with new ones; if 20% of the bolts are found to be loose to less than 80% of the specified torque, all the bolts are replaced with new ones. After the cumulative work of the equipment reaches 14000 hours, all the bolts are replaced with new ones (Heavy sincerity is recommended: after two to four months use, the solid parts are re-strengthened, and then transition to the annual systematic inspection).

6、In use to pay close attention to the operation of the slewing ring, such as noise, impact, power suddenly increased, should immediately stop to check until all faults are eliminated, if necessary, need to disassemble and check.

7、Slewing bearing in use, prohibit the direct flushing of water slewing bearing, to avoid water into the raceway caused by rust; strictly prevent the harder foreign body close to or into the engagement area, so as not to cause tooth injury or unnecessary trouble.

If you have any more question when you use the slewing ring bearing, just feel free to contact us!

Post time: Apr-22-2021