News

-

Causes of slewing bearing

For equipment such as slewing bearings, accuracy requirements are often high. Once installed, used or maintained improperly, various problems may arise, such as excessive shaking when the slewing bearing is used. The main reasons for the shaking of the slewing bearing are as follows: 1. The inst...Read more -

Introduction of Xuzhou Wanda Slewing Bearing Exhibition Hall

XZWD slewing bearing completed the company’s internal exhibition hall in June 2022. The exhibition hall mainly includes three aspects: company and product display area, type test area and laboratory. First introduce our XZWD company and products displayed. The section of the south wall main...Read more -

Xuzhou Wanda Slewing Bearing Observation Activity

“Keep improving, create high-quality products, continuous improvement, and customer satisfaction” is our quality policy and the goal of our XZWD Slewing Bearing Co., Ltd. ——General Manager Xu Zhengkun On July 16, colleagues from Jiangsu Shuangzheng Machinery Co., Ltd. came to XZW...Read more -

Maintenance method of the slewing bearing of the crane

The slewing bearing of the crane crane is an important “joint” of the crane, so its maintenance is very important. Some of the working characteristics of cranes are intermittent motion, that is, the corresponding mechanisms of reclaiming, moving, unloading and other actions in a worki...Read more -

Light excavator slewing bearing replacement

The slewing bearing of a light excavator is easily damaged. Usually the replacement cycle is 2 to 3 years. In this case, the main bearing failure is the broken teeth of the slewing ring, abnormal noise when rotating or the slewing ring bearing is stuck. When this happens, stop the operation immed...Read more -

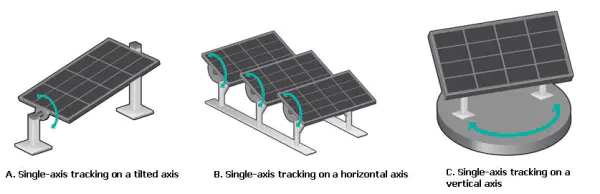

Single-axis and Dual-axis Solar Tracker

The conversion efficiency of solar photovoltaic panels is highest when incident light hits the panel surface perpendicular to the panel plane. Considering the sun is a constantly moving light source, this only happens once a day with a fixed installation! However, a mechanical system called a sol...Read more -

Double Worm Slewing Drive

Double worm slewing drive is a brand new slewing drive product, which consists of outer casing, worm gear ring, worm, motor and other components. Compared with the single worm slewing drive, the double worm slewing drive still has the characteristics of modularization, s...Read more -

How to do the slewing ring bearing lubrication?

When the slewing bearing leaves the factory, a small amount of grease is applied to the raceway. Before use, the user should refill with new grease according to different working conditions. Notice: 1. Clean the tooth surface, apply or spray grease to completely c...Read more -

Classification of Pinion Splines

Owing to the spline connection transmission has a large contact area, high bearing capacity, centering performance and good guiding performance, shallow keyway, small stress concentration, small weakening of the strength of the shaft and hub, and tight structure. Therefore, it is often used for s...Read more -

Wind turbine slewing bearing

In recent years, with the rapid economic development and population expansion, the demand for energy is also increasing. It directly leads to the aggravation of energy reduction and environmental pollution. The country is vigorously developing clean energy, and wind power is a mature, large-scale...Read more -

Large Gear Ring For Excavator Slewing Bearing

When the excavator has abnormal noise when it is rotating, if there is a noise in a certain position during the full revolution, it must be tested. Consider whether the pinion gear and the large ring gear have broken teeth. At the same time, tooth fracture of large ring ...Read more -

Maintenance of Hydraulic Excavator Slewing Bearing

Hydraulic excavators generally use single-row 4-point contact ball internal tooth slewing bearings. When excavator is working, the slewing bearing bears complex loads such as axial force, radial force, and tipping moment, and its reasonable maintenance is very important. The maintenance of the sl...Read more