At present, we provide slewing bearings for wind power to Korean customers. Good feedback from customers is our company’s progress in the wind power industry.

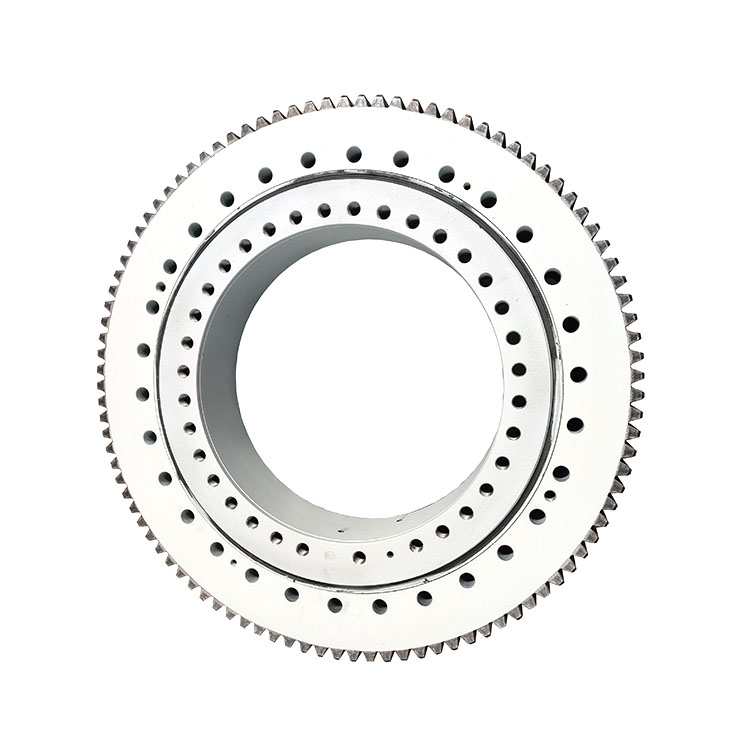

The special slewing bearing for wind power generators is a kind of extra-large bearing, mainly used for pitch and yaw systems. The load is complicated and the disassembly and maintenance are very difficult. Therefore, the design and manufacturing requirements of wind power slewing bearings are strict.

The wind turbine uses one set of yaw slewing bearings and three sets of pitch slewing bearings. The material of the yaw and pitch bearing ring is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the raceway surface is quenched. The force of yaw and pitch slewing bearings is complex, and the impact and vibration are relatively large. Therefore, the slewing bearing is required to withstand both impact and large load.

Many large multinational companies are still studying which form of wind power slewing ring, especially pitch slewing ring, is still under study. Judging from the current installed capacity, the pitch slewing ring mostly uses double-row four-point contact ball slewing ring. Yaw slewing bearings mostly use single-row four-point contact ball slewing bearings, and a small number of them use cross-roller slewing bearings or other forms. Although the domestic standards stipulate the structural form of the pitch and yaw slewing bearing, it does not give a reasonable explanation.

Post time: Aug-13-2021