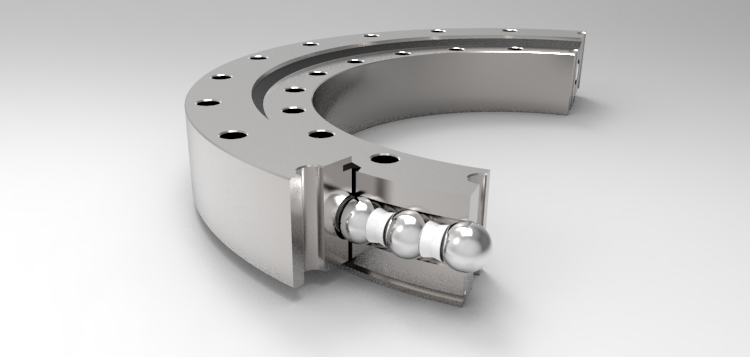

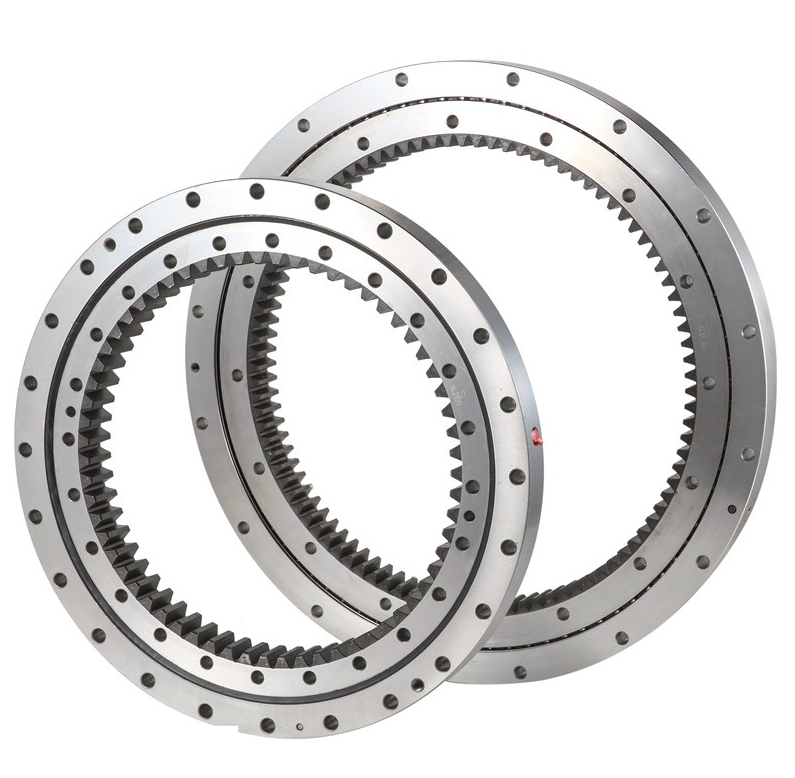

Slewing bearings are usually separated from the rolling elements by individual spacer. This structure can maintain the smoothness of the movement, and is widely used because of its low price. Special application require special ball or spacer, such as copper, aluminum, and other high-temperature resistant spacer. The bearings usually mounted on the horizontal axis or continuous rotation of the generator and the high requirements for positioning and reliability of the occasion used in the slewing bearings, can be used in the strip combination cage, so that the rolling body in the correct circumferential position, more reliable.

The causes and solutions of heat generation caused by structural factors of the Slewing bearing:

① the shaft size of the slewing bearing is too large, so the bearing will be tighter Solution: provide the appropriate tolerance for the shaft, and strictly prohibit over-tightening.

② The aluminum three-layer ring seal has friction leading to heat Solution: The seal hole and ring should be coated with grease to reduce friction resistance when installed.

③ slewing bearing seat coated with too much grease or oil level is too high Solution: slewing bearing will be through the seal hole to remove excess grease, oil lubrication will be oil level down to just below the bearing box.

④ inner ring and seal ring friction heating Solution: this time to stop and check the clamping ring screws, ensure that the inner ring is firmly attached to the shaft, ensure that the free bearing is installed correctly, the roller and outer ring centerline alignment.

In addition to the slewing bearing structure reasons, there are other reasons will cause heating, as follows.

⑤ Improper grease or lubricant type leads to lubricant failure Solution: Re-select the appropriate lubricant type.

⑥ Low oil level and insufficient grease Solution: The oil level on the outer side of the shaft diameter should be exactly below the cage and filled with suitable grease.

Of course, there may be many reasons that cause the slewing ring to overheat, in order to ensure the normal use of the slewing ring, I hope you encounter the phenomenon of slewing ring overheating, can stop in time to check, find the cause and deal with it, to prevent the shortening of the service life of the slewing ring.

Slewing bearing working principle is very simple: the way to move the object has sliding into rolling, reduce friction resistance.

Specifically, the slewing bearing mainly relies on lubrication and friction to achieve the result of operation. In the internal, it relies on the mutual friction of the ball and steel ring to play the purpose of operation, in the external, also relies on the friction of the slewing bearing and other parts to start the operation, mutual friction, thus driving the object operation. As its use is mostly to carry heavy large objects, so its own centripetal force requirements are very high, which is also the decision of its working principle, so in terms of materials also need to be able to ensure the quality of steel.

Of course, friction alone is still not enough. Although it is to rely on friction in order to operate, but lubrication is also essential. Just like the chain of a bicycle, when it is used for a long time, the friction is too great and it will also affect the use of the parts. So after using this kind of bearing for some time, we should carry out timely maintenance and brush some lubricating oil to ensure that it can work in a more suitable environment with high.

Post time: Apr-21-2021