One of Hottest for Vertical Slewing Drive - General Introduction of The Slewing Drive – Wanda

One of Hottest for Vertical Slewing Drive - General Introduction of The Slewing Drive – Wanda Detail:

Slewing drive SE Series

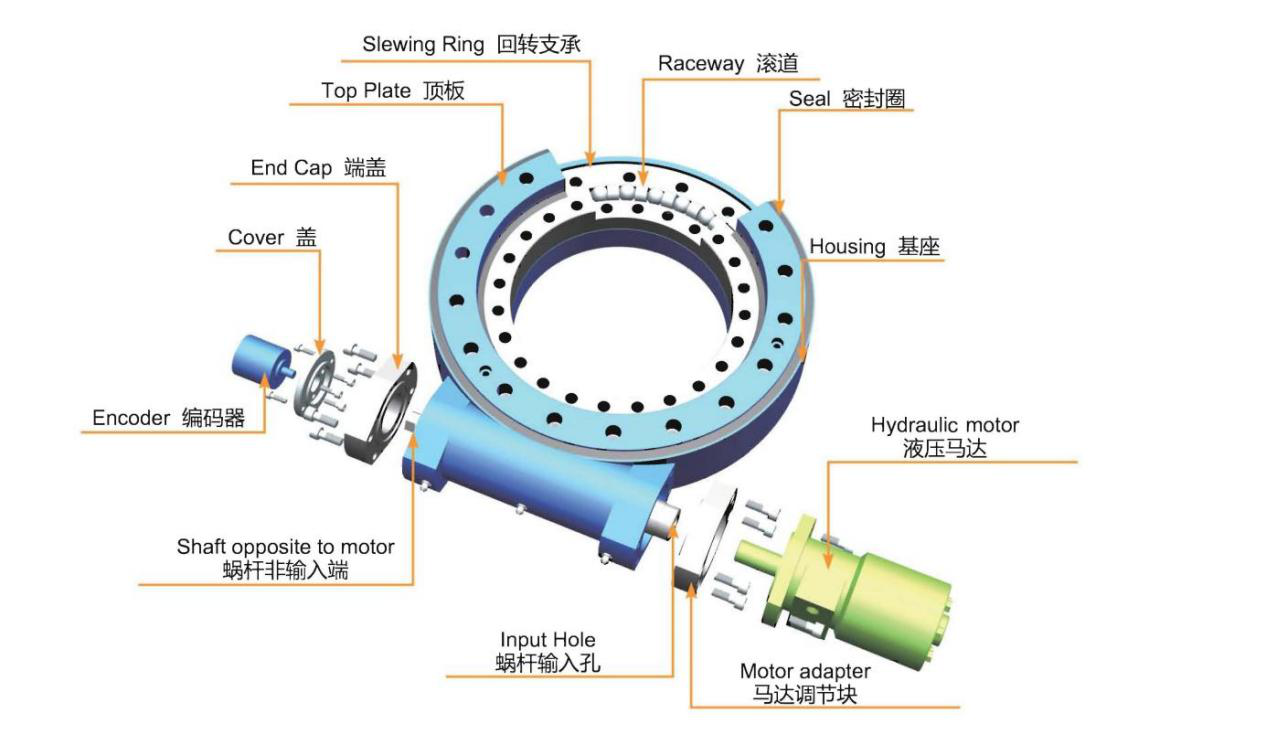

SE series is an enclosed housing type of the slewing drive. The worm gear drive can realize reverse self-locking. The enclosed housing slewing drive mainly applies to the relatively high condition for high requirement for dust-proof, rain-proof and anti-corrosion occasion. The ingress protection grade is IP65. From dimensions 3” to 25” and with physical capacity performances from small to large, presently our SE series includes models SE3, SE5, SE7, SE9, SE12, SE14, SE17, SE21, SE25. More models are under further development.

Slewing drive WEA Series

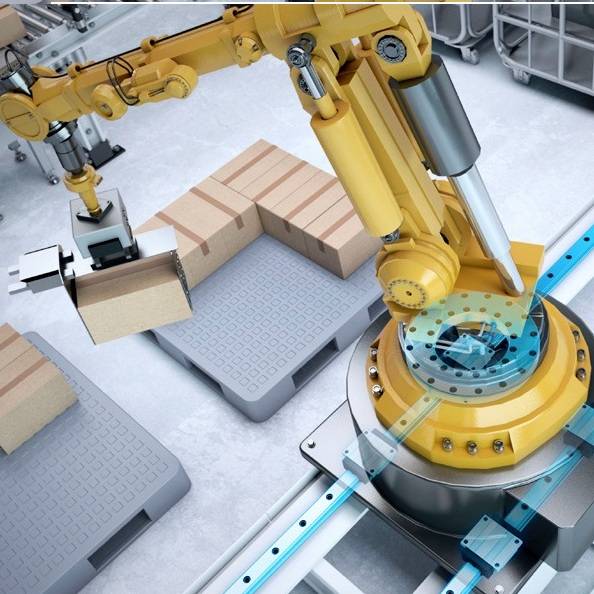

WEA series is a heavy-duty slewing drive. Compared with SE series, WEA series has the advantages of better protection performance, large transmission torque, good impact resistance and long service life. WEA series slewing drives are widely used in relatively rotating parts in the field of machinery and solar tracking system, aerial work machinery, slewing chassis, truck crane, rock drill, drilling machine, wood grabber, code word forming machine, etc. From dimensions 3” to 25” and with physical capacity performances from small to large, presently our WEA series includes models WEA7, WEA8, WEA9, WEA12, WEA14, WEA17, WEA21, WEA25. More models are still in development.

Dual-Worm Slewing Drive

Same with the single-worm slewing drive, the double-worm slewing drive still has the characteristics of modularization, safety and simplified main engine design. Different from the single-worm slewing drive, under the similar external size, the double-worm slewing drive has a more compact structure and higher load. Better capability and output torque exceeds that of a single-worm rotary drive. A single-worm slewing drive can be equipped with only one motor, while a dual-worm slewing drive can be equipped with two motors. Currently our available dual-worm slewing drives are models SE17-2, SE21-2, WEA17-2 and WEA21-2. More dual-worm models are under development.

We can provide regular models for customers.

We can provide different colors for customers.

We can make a change or design of new models for customers.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for One of Hottest for Vertical Slewing Drive - General Introduction of The Slewing Drive – Wanda , The product will supply to all over the world, such as: Kuwait, Moldova, Netherlands, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!