Professional China Excavator Slewing Ring Bearing - XZWD solar power generation single row ball slewing bearing – Wanda

Professional China Excavator Slewing Ring Bearing - XZWD solar power generation single row ball slewing bearing – Wanda Detail:

Ball slewing ring is lubricated every 100 hours ,roller slewing ring is lubricated every 50 hours.Fill the raceway with grease till it is seeping from the seals.Also check the pre-tightening force of slewing ring , must keep enough pre-tightening force.

Give you attention to the runing slewing ring,you should stop it to check when noise,impulsion or other problem unable to run .Trouble shooting and guarantee the operation will not have any problem.

About cleaning,it can not cleaning with water directly , prevent water into the raceway, prevent hard object or debris into the raceway and lead to the teeth of slewing ring teeth mismatch.

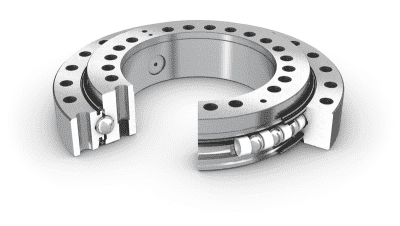

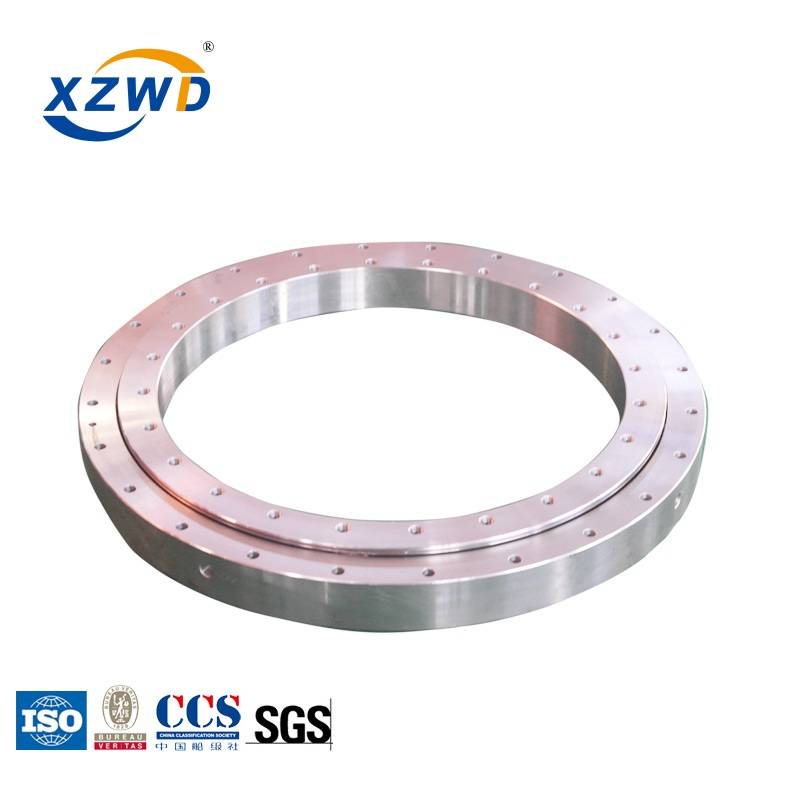

Slewing bearing generally includes mounting holes, lubricants hole and sealing devices.

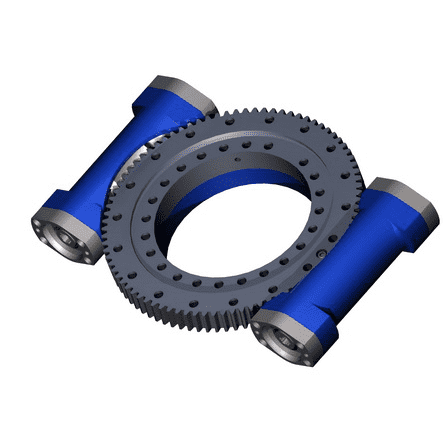

Slewing bearing forms include single row four-point contact ball bearings, double row ball bearing, single row crossed roller bearing and three rows of cylindrical roller bearing .

1. Single row four-point contact ball bearings has the high dynamic load capacity,main application dynamic mechanical which requirements higher dynamic.Such as crane, excavator and so on.

2. Double row ball bearings and three row roller bearing , due to improve the carrying capacity of attention to the bearing height direction, various load respectively by different raceway and roller group, so under the same loading condition, so it make the host more compactly, it is a kind of high bearing capacity slewing ring.

3. Single row crossed roller bearing has high Static load capacity ,main application the stillness equipment at work.And four-point contact ball slewing bearing just opposite.

Three row roller bearing due to the large size of axial and radial,it is main application heavy duty machinery.such as ship crane,ladle turret and heavy duty mobile machinery

Slewing ring can use in different industries, but in all cases will cause the damage of the slewing ring, and the damage was found in the slewing bearing, but don”t know where the damage, can only be found damage to comprehensive anatomy.

During the disassembly of slewing bearing, the outer ring of slewing bearing connected the upper part of machinery, the inner ring of slewing bearing connected the down part of machinery. Cleaning the seal and lifting the machinery separate, then take the screws and bolts out.

Take out the steel ball and isolation block and inspection on steel ball and isolation, if isolation block have crack or damage please replacement timely.Clean the steel ball and in the sun light to watch, you can see clearly if there has pitting or pits on the steel ball.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Professional China Excavator Slewing Ring Bearing - XZWD solar power generation single row ball slewing bearing – Wanda , The product will supply to all over the world, such as: Lesotho, Norwegian, Bhutan, Our company always provides good quality and reasonable price for our customers. In our efforts, we already have many shops in Guangzhou and our products have won praise from customers worldwide. Our mission has always been simple: To delight our customers with best quality hair products and deliver on time. Welcome new and old customers to contact us for the future long term business relationships.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.