Renewable Design for Internal Gear Bearing - XZWD slewing bearings for wind turbine pitch and yaw positions – Wanda

Renewable Design for Internal Gear Bearing - XZWD slewing bearings for wind turbine pitch and yaw positions – Wanda Detail:

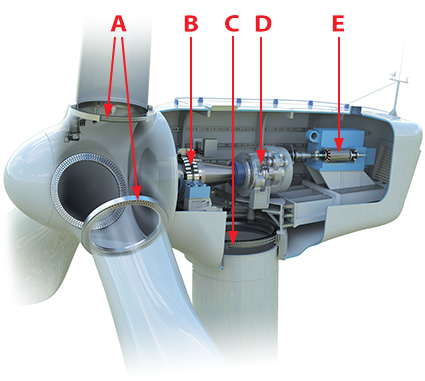

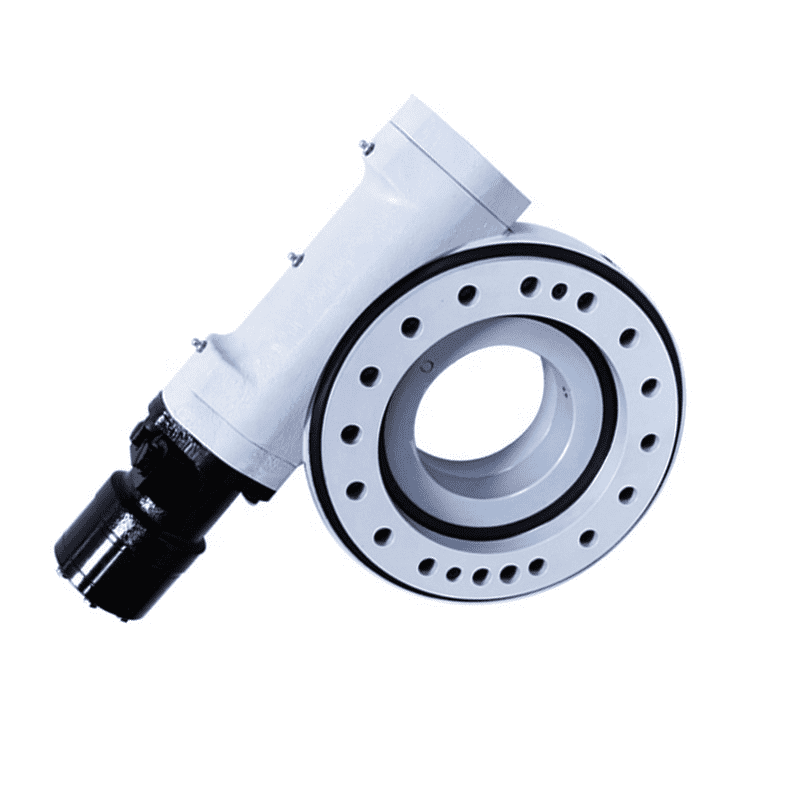

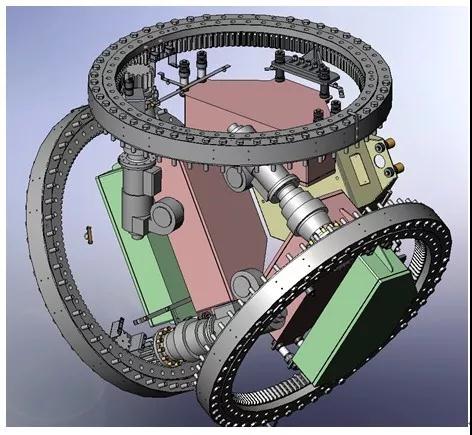

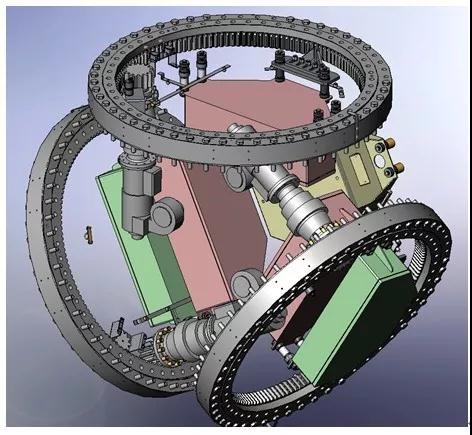

Wind turbine slewing bearings can also be called wind power bearings. They are a special kind of bearings. They are used in harsh environments, have high maintenance costs and require long life. Slewing bearings for wind turbines mainly include: yaw bearings, pitch bearings, spindle bearings, variable speed bearings, box bearings, generator bearings.

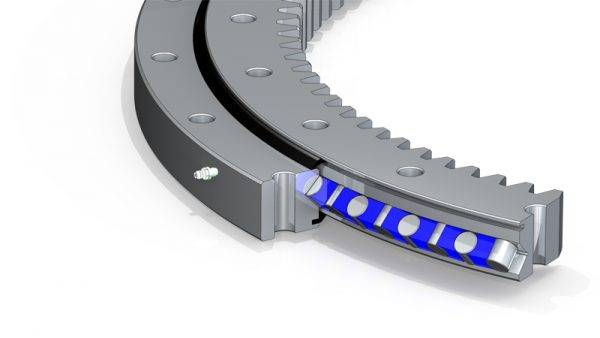

The structural forms of slewing bearings for wind turbines mainly include four-point contact ball slewing bearings, crossed roller slewing bearings, cylindrical roller bearings, spherical roller bearings, and deep groove ball bearings. The yaw bearing is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub.

The structural forms of slewing bearings for wind turbines mainly include four-point contact ball slewing bearings, crossed roller slewing bearings, cylindrical roller bearings, spherical roller bearings, and deep groove ball bearings. The yaw bearing is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub.

Judging from the current installation and usage, the pitch slewing bearings mostly use double-row four-point contact ball slewing bearings, the yaw slewing bearings mostly use single-row four-point contact ball slewing bearings, and a small amount of cross-roller slewing bearings or other forms are used.

(A) Pitch bearings

(B) Main shaft bearing

(C) Yaw bearing

(D) Gearbox bearings

(E) Generator bearings

We,xuzhou wanda slewing bearing has designed and manufactured slewing bearings for wind turbine pitch and yaw positions. You can contact us if you have any request.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for Renewable Design for Internal Gear Bearing - XZWD slewing bearings for wind turbine pitch and yaw positions – Wanda , The product will supply to all over the world, such as: Dominica, Singapore, Argentina, With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.