Slewing Bearing

-

Factory supply replacement 330/340 slewing ring turntable bearing

Single ball slewing bearing is widely used in truck crane. Slewing bearing is composed of upper and lower seat rings, which can handle the loading and unloading of goods more comprehensively. Compared with other steering equipment, the superiority of slewing bearing is the key to solve the problem of inaccurate goods placement and loading and unloading.

-

Slewing bearing For Heading Machine

The slewing bearing is also called the slewing bearing, and some people also call it: rotating bearing, slewing bearing. The English names are: slewing bearing, slewing ring bearing, turntable bearing, slewing ring. Slewing bearings are widely used in the real industry. They are called “joints of machines”. They are mechanical places that require relative rotational movement between two objects, but also need to bear axial force, radial force, and tilting moment at the same time. An important transmission component necessary. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, engineering machinery, light industry machinery, metallurgical machinery, machinery, industrial machinery and other industries.

-

Slewing Ring For Excavator Parts Unic And Tadano

The slewing bearing is also called the slewing bearing, and some people also call it: rotating bearing, slewing bearing. The English names are: slewing bearing, slewing ring bearing, turntable bearing, slewing ring. Slewing bearings are widely used in the real industry. They are called “joints of machines”. They are mechanical places that require relative rotational movement between two objects, but also need to bear axial force, radial force, and tilting moment at the same time. An important transmission component necessary. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, engineering machinery, light industry machinery, metallurgical machinery, machinery, industrial machinery and other industries.

-

Light Type Slewing Bearing For Canning Machine

The light slewing bearing has the same structure with four point contact ball slewing bearing, but the weight is ligh and could be used for some light type machinery applications.

The light slewing bearing ring has been widely used in many applications:

Food Machinery

Canning Machinery

Environmental Machinery

-

Slewing Bearing For Robert

The slewing bearing is also called the slewing bearing, and some people also call it: rotating bearing, slewing bearing. The English names are: slewing bearing, slewing ring bearing, turntable bearing, slewing ring. Slewing bearings are widely used in the real industry. They are called “joints of machines”. They are mechanical places that require relative rotational movement between two objects, but also need to bear axial force, radial force, and tilting moment at the same time. An important transmission component necessary. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, engineering machinery, light industry machinery, metallurgical machinery, machinery, industrial machinery and other industries.

-

Flange Type Light Slewing Bearing For Rotating Platform

The slewing bearing is also called the slewing bearing, and some people also call it: rotating bearing, slewing bearing. The English names are: slewing bearing, slewing ring bearing, turntable bearing, slewing ring. Slewing bearings are widely used in the real industry. They are called “joints of machines”. They are mechanical places that require relative rotational movement between two objects, but also need to bear axial force, radial force, and tilting moment at the same time. An important transmission component necessary. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, engineering machinery, light industry machinery, metallurgical machinery, machinery, industrial machinery and other industries.

-

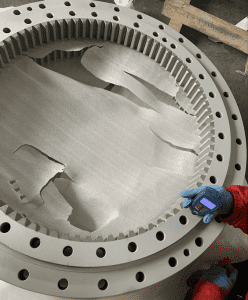

High Preicision Slewing Bearing Three Row Roller Type large ring

Three-row roller slewing bearing is equipped with seat-rings, upper orbit. Neither orbit and radial orbit is seperated individually, it makes the load of each row of the rollers can be confirmed, making it can undertake all kinds of different load simultaneously. Three row roller slewing bearing’s carring capacity is the biggest among four models and the axial and radial size arre rather large to some extent, the structure of the three roww roller slewing bearing ring is very firm.

-

Slewing bearing for lamp maintenance aerial work vehicles

The vehicle-mounted aerial work vehicle usually adopts a full-slewing slewing mechanism, and the forward and reverse directions can be selected according to the needs of the operation. Both the slewing part of the slewing mechanism and the work platform are installed on the slewing bearing.

-

Thermal Spray Zinc Slewing bearing For Marine

Advantages of hot-sprayed zinc

1. The temperature of the thermal spray zinc spraying process is very low, the surface temperature of the workpiece is <80℃, and the steel workpiece is not deformed.

2. The hot zinc spraying process is adopted, and the zinc spraying method can be used for repairing on site to avoid process breakage.

3. The pretreatment of thermal zinc blasting process adopts sandblasting, so the surface of the workpiece has roughness, the coating adhesion is good, and the tensile strength is ≥6Mpa.

4. The thermal spray zinc adopts pure zinc thermal spray, which has a better anti-corrosion effect and can achieve the purpose of 20 years of long-term anti-corrosion.

The application of hot-sprayed zinc to cold-sprayed zinc is different. Hot-sprayed zinc is mainly used for spraying on large-scale steel structures, bridges, buildings, etc., and is used in projects such as heavy anti-corrosion, marine engineering, and long-term protection.

-

Slewing Bearing For PC200

The slewing bearing is also called the slewing bearing, and some people also call it: rotating bearing, slewing bearing. The English names are: slewing bearing, slewing ring bearing, turntable bearing, slewing ring. Slewing bearings are widely used in the real industry. They are called “joints of machines”. They are mechanical places that require relative rotational movement between two objects, but also need to bear axial force, radial force, and tilting moment at the same time. An important transmission component necessary. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, engineering machinery, light industry machinery, metallurgical machinery, machinery, industrial machinery and other industries.

-

Slewing Bearing For Caterpillar Excavator

The slewing bearing is also called the slewing bearing, and some people also call it: rotating bearing, slewing bearing. The English names are: slewing bearing, slewing ring bearing, turntable bearing, slewing ring. Slewing bearings are widely used in the real industry. They are called “joints of machines”. They are mechanical places that require relative rotational movement between two objects, but also need to bear axial force, radial force, and tilting moment at the same time. An important transmission component necessary. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, engineering machinery, light industry machinery, metallurgical machinery, machinery, industrial machinery and other industries.

-

2021 non gear small bearing model 010.20.250 slew turntable bearing

Our factory,XZWD slewing bearing co.,ltd can produce both standard and non-standard products.

As meeting customers’ demand is our service principle.

We provide spot, generation processing, drawing processing, sample processing, free design and other services.