Three row roller turntable slewing bearing external gear 131.32.800

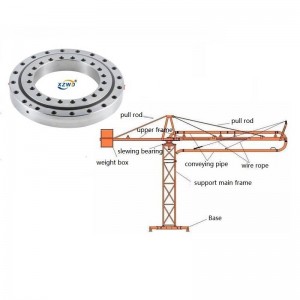

Three row roller slewing bearing has three seat rings, upper and lower and radial raceways are separated respectively, so that the load of each row of rollers can be accurately determined and can bear various loads at the same time. It is one of the four products with the largest bearing capacity. The axial and radial dimensions are large and the structure is firm. It is especially suitable for heavy machinery requiring larger diameter, such as bucket wheel excavator and wheel type lifting machine Heavy machinery, marine crane, ladle slewing and large tonnage truck crane and other machinery.

The single row cross roller slewing bearing is similar to the four point contact spherical slewing bearing, with only one row of rolling elements, which are short cylindrical rollers; the axes of adjacent rollers are arranged in a 90 ° cross; there are two raceways in the inner and outer rings, and the raceway section is linear. Half of the rollers bear the downward axial force and the half bear the upward axial force.

The single row four point contact ball slewing bearing has a row of steel balls as rolling element, and there is a single isolation block between the steel balls. The inner and outer rings are integral, and the steel balls are loaded through the filling holes. The ball is in contact with four points of raceway and can bear axial force, radial force and overturning moment at the same time.

These two kinds of slewing bearings have their own characteristics. As the contact angle between the roller and the roller of the slewing bearing is larger than that of the ball bearing, the contact angle between the roller and the ball bearing will be larger than that of the ball bearing. Therefore, considering that the vibration of the boom should be as small as possible, the cross roller slewing bearing should be preferred.

Three row roller slewing bearing is an important transmission component. In order to achieve relative rotation, it needs to bear a lot of force during the operation. With the wide use of various mechanical equipment, three row roller slewing bearing is the most important part of the equipment. Essential accessories are widely used in various construction machinery, medical machinery and industrial equipment, and have been highly recognized. The external gear of light series slewing bearing is an essential product in three row roller slewing bearing. If the equipment is worn during operation, it can be lubricated between multiple parts to reduce friction and tear. It is better to stop the equipment and conduct detailed inspection to enhance the operation of the whole mechanical equipment. meanwhile

In order to prolong the service life of the three row roller slewing bearing in the machine, it is usually best to pay attention to the corrosion of the product to the corrosive product and take anti rust measures. Usually, clean the surface regularly and use the cleaning effect. It is better to keep the product surface dry at the same time, pay attention to the application of anti rust oil, if you encounter special circumstances, you can choose to use antirust oil. In fact, three row roller slewing bearing is a very good product. It is better not to touch it with hands when not in use, so as not to corrode the bracket.

As an important part of industrial parts, three row roller slewing bearing is the biggest problem faced by industry. There was no improvement. Only by continuous research and development, improving product design and structure, can the industry have better development and momentum. For example, in the production process of parts, the accuracy problem is still very worthy of our attention. At present, the accuracy of the parts is about minus 0.5mm, but we should also pursue more accurate and more accurate precision, such as 0.2mm, only enough target. This product can get new development.

Another example is the material built on a three row roller slewing ring, which is also a big problem. The alloy used more than ten years ago has not been improved, so attention must also be paid to it. It should be more appropriately designed and new materials that are easy to use should be used. Finally, parts are used in the structure. Now, this support usually consists of four parts. We don't seem to care that support can be divided into three parts or even parts. In this respect, we need to invest enough manpower and resources.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.