Well-designed Slewing Unit - XZWD | External gear Precision Crossed roller Slewing Bearing – Wanda

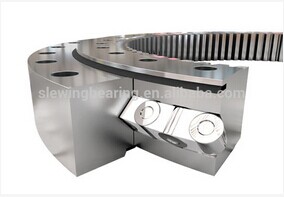

Well-designed Slewing Unit - XZWD | External gear Precision Crossed roller Slewing Bearing – Wanda Detail:

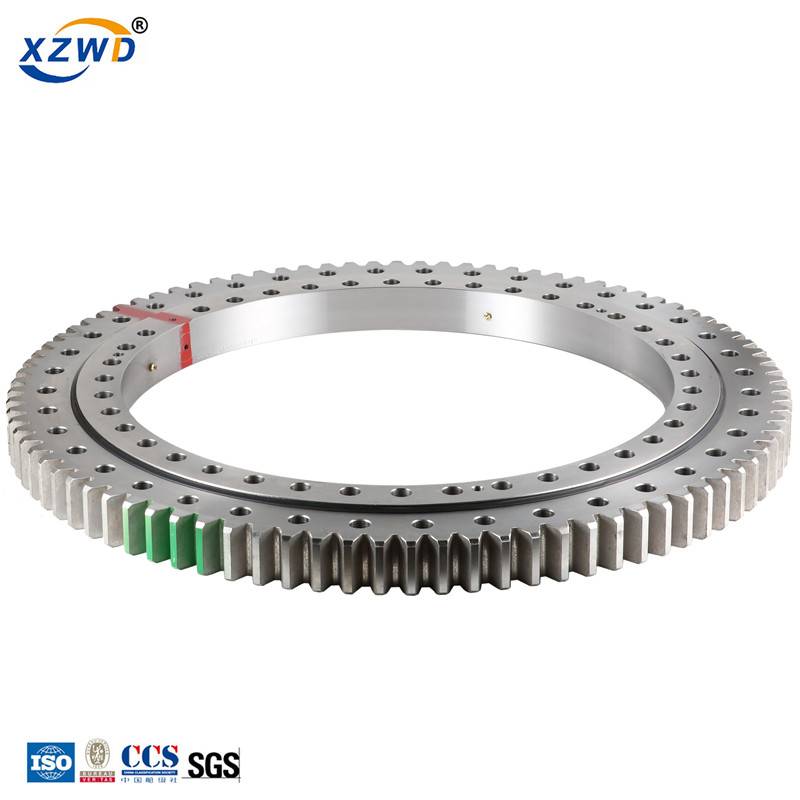

slewing bearing, slewing drives, which are mainly applied in port machinery, mining machinery, welding machinery, construction vehicles, modular vehicles, single or dual axis solar tracking systems, and small wind power systems etc.

Slewing bearing/drives can bear axial force, radial force and tilting moment.The diameter range of slewng bearing can be from 200 mm to 5000 mm For slewing drive, there are nine (9) different sizes available from 3″ to 25″ with more than 60 models to meet both regular and precise tracking requirements in PV, CPV and solar thermal power tracking fields.For detailed information please download our catalogue.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Well-designed Slewing Unit - XZWD | External gear Precision Crossed roller Slewing Bearing – Wanda , The product will supply to all over the world, such as: Florence, Washington, Turkey, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

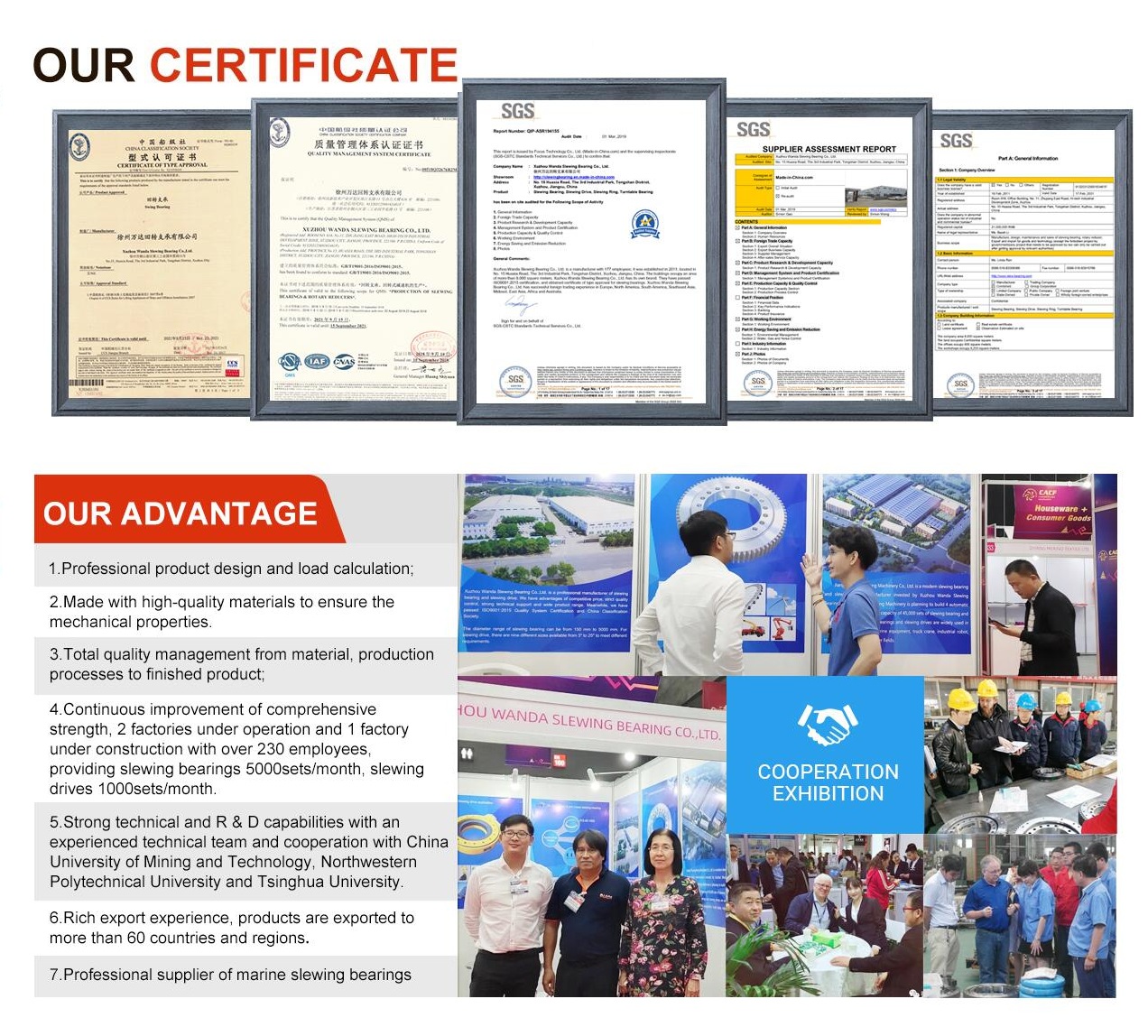

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!