Wholesale Price Bearing Slew Drive - Hot sale Stock Welding Positioner machine SE12 Slewing drive – Wanda

Wholesale Price Bearing Slew Drive - Hot sale Stock Welding Positioner machine SE12 Slewing drive – Wanda Detail:

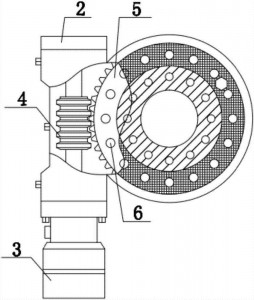

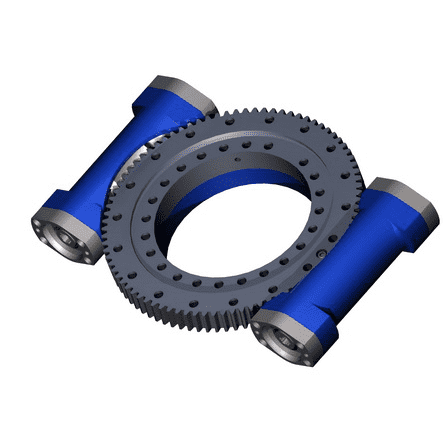

The slewing drive is mainly composed of a worm, a support, and a shell. It has the characteristics of dustproof, rainproof, corrosion-proof, low speed, and self-locking.

Slewing drive mainly applied in port machinery, mining machinery, welding machinery, construction vehicles, modular vehicles, single and dual axis solar tracking systems,

and small wind power systems etc.

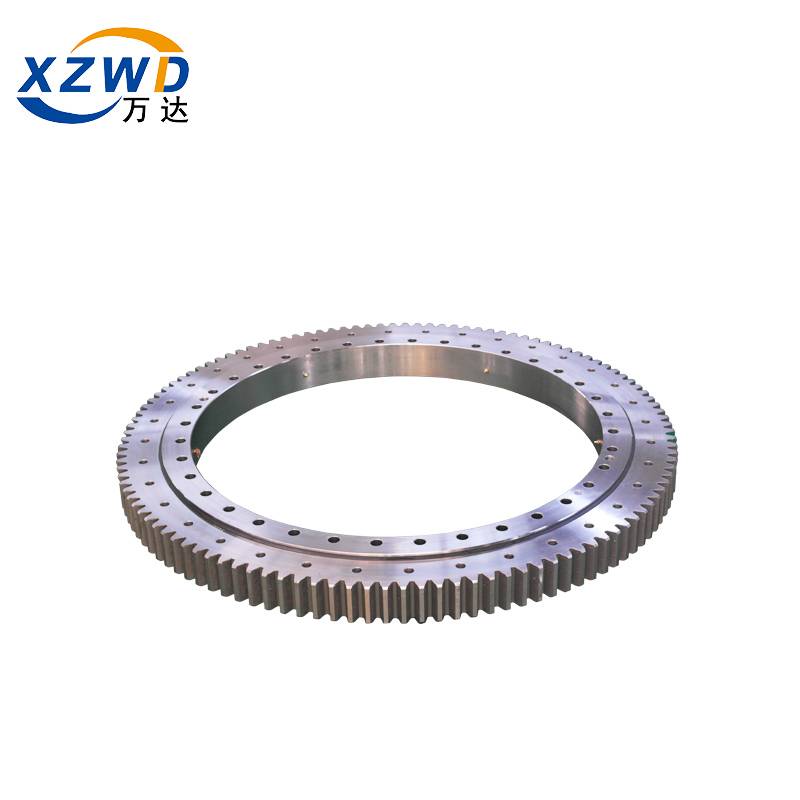

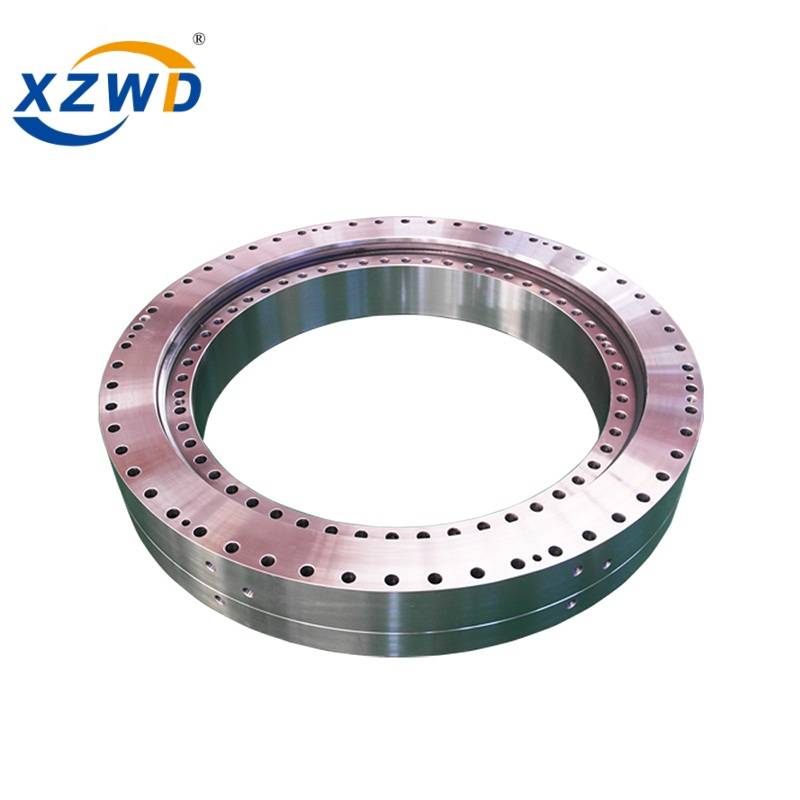

There are mainly SE Series and WEA Series to meeth both regular and precise tracking requirement. The size from 3″ ~ 25″ , and all models we have stock and we can deliver the goods within 5days.

We also have dual worm slewing drive for a little bigger slewing drive from 14″ ~ 25″.

SE Series and WEA Series have different type of gear. SE Series have helical gear and WEA Series have worm gear, WEA Series is Heavy type mainly used for construction machinery.

Product detail pictures:

Related Product Guide:

Car parking system used slewing bearing

Adhering for the theory of "quality, services, performance and growth", we have received trusts and praises from domestic and worldwide shopper for Wholesale Price Bearing Slew Drive - Hot sale Stock Welding Positioner machine SE12 Slewing drive – Wanda , The product will supply to all over the world, such as: Toronto, Victoria, Iraq, We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.