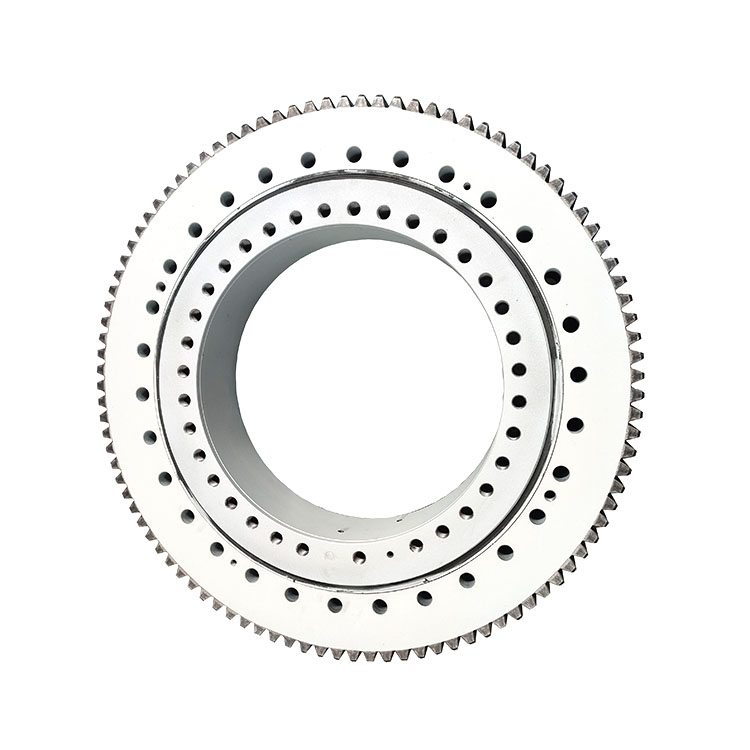

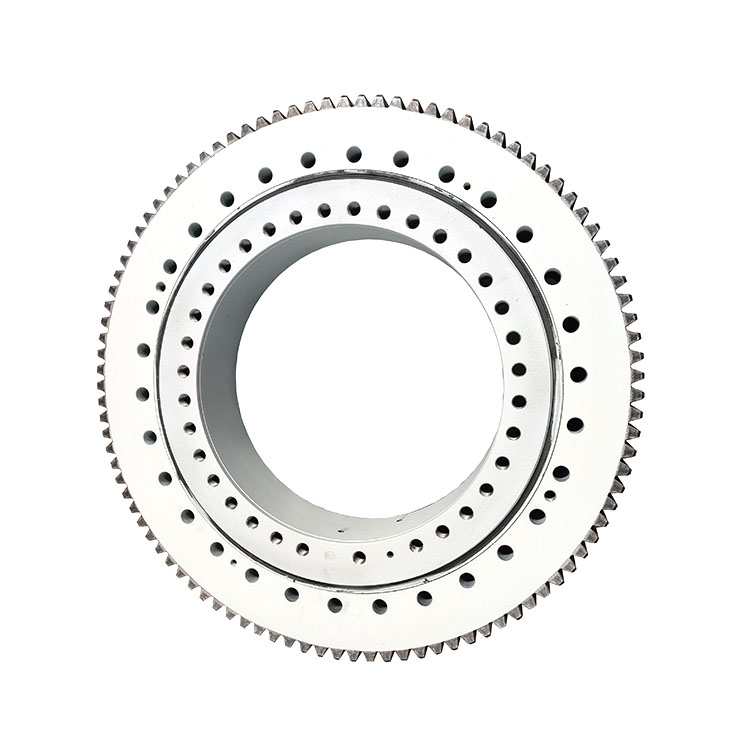

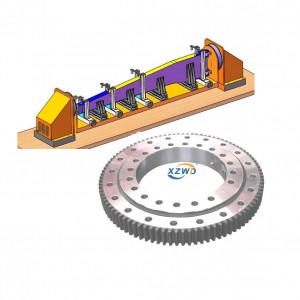

XZWD External gear Slewing bearing for Wind power

At present, we provide slewing bearings for wind power to Korean customers. Good feedback from customers is our company’s progress in the wind power industry.

The special slewing bearing for wind power generators is a kind of extra-large bearing, mainly used for pitch and yaw systems. The load is complicated and the disassembly and maintenance are very difficult. Therefore, the design and manufacturing requirements of are strict.

The wind turbine uses one set of yaw slewing bearings and three sets of pitch slewing bearings. The material of the yaw and pitch bearing ring is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the raceway surface is quenched. The force of yaw and pitch slewing bearings is complex, and the impact and vibration are relatively large. Therefore, the slewing bearing is required to withstand both impact and large load.

Many large multinational companies are still studying which form of wind power slewing ring, especially pitch slewing ring, is still under study. Judging from the current installed capacity, the pitch slewing ring mostly uses double-row four-point contact ball slewing ring. Yaw slewing bearings mostly use single-row four-point contact ball slewing bearings, and a small number of them use cross-roller slewing bearings or other forms. Although the domestic standards stipulate the structural form of the pitch and yaw slewing bearing, it does not give a reasonable explanation.

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.