Stronger anti-rust Stainless steel slewing bearings

The materials used for conventional slewing rings are generally high-alloy structural steels such as 50Mn and 42CrMo. However, some customers choose stainless steel for special purposes. XZWD slewing bearing co., ltd. specially designed stainless steel slewing ring to meet different usage.

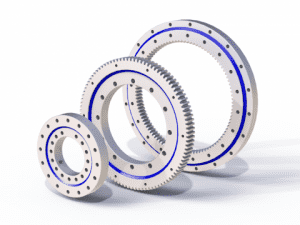

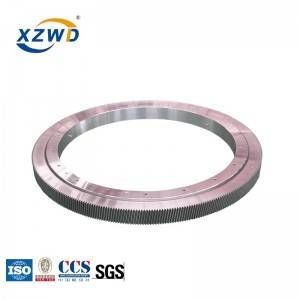

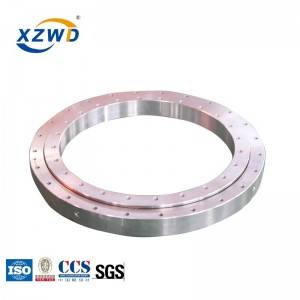

Compared with ordinary slewing bearings, stainless steel slewing bearings have stronger rust and corrosion resistance. Choosing suitable lubricants and sealing can be used at -60℃~+300℃. Stainless steel slewing bearing can resist corrosion caused by humidity and several other media. This type of single-row ball slewing bearing is the same as the standard slewing bearing made of high-alloy structural steel. It has a deep slewing ring raceway, and the matching degree between the slewing ring raceway and the ball is extremely high. Because of its high mechanical strength and large load capacity, stainless steel slewing bearings are widely used in food processing, medical equipment, pharmaceutical machinery, etc.

XZWD Slewing Ring Co., Ltd. is located in China’s construction machinery capital-XUZHOU CHINA, where XCMG Group is located. Our company has been engaged in the production and design of slewing bearings about 20 years. The products are sold all over the country and exported to the United States, Britain, France, Malaysia, Singapore, Germany, Japan, Brazil, Russia, Czech Republic, Finland, Netherlands, Sweden, Ireland, Turkey, UAE , Canada, Spain and other 42 countries, the products have been widely approved and recognized by users.

You can choose the suitable model of the slewing ring bearing specifications:

1. Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008.

2. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements.

3. With abundant raw materials and high production efficiency, the company can supply products to customers as quickly as possible and shorten the time for customers to wait for products.

4. Our internal quality control includes first inspection, mutual inspection, in-process quality control and sampling inspection to ensure product quality. The company has complete testing equipment and advanced testing method.

5. Strong after-sales service team, timely solve customer problems, to provide customers with a variety of services.